SolMotionCase Study

3D Object Positioning with Vision Guided Robotics

Handling Automotive Parts for Assembly

Case

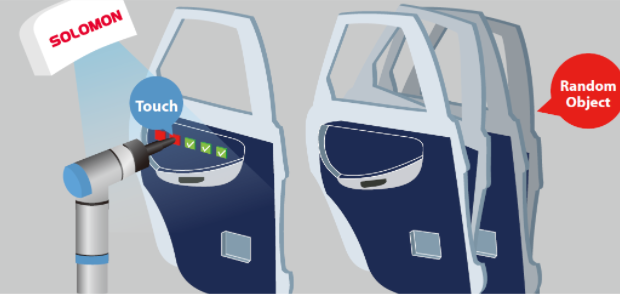

Detecting and Testing Electric Car Doors

In automotive production, various components must be located and tested along the assembly line before finalizing the cars. Electric car doors, for instance, require pressing each door button to ensure full functionality. However, in a conventional production line where different car models are manufactured interchangeably, the varying sizes and designs of doors can cause positional shifts, leading to incomplete quality checks as the robot may miss buttons.

Challenge

Overcoming Rigidity in Traditional Manufacturing

In traditional automotive manufacturing, the production process relies on fixed positions for objects and tools. Regular robots used in this setup lack the ability to adapt their movements according to the location of production parts or determine if an object is correctly placed. Consequently, addressing this limitation often involves employing complex positioning systems or expensive sensors, leading to longer changeover times. As manufacturing lines are now expected to produce a greater variety of products at lower volumes, these challenges pose significant hurdles in the industry.

Solution

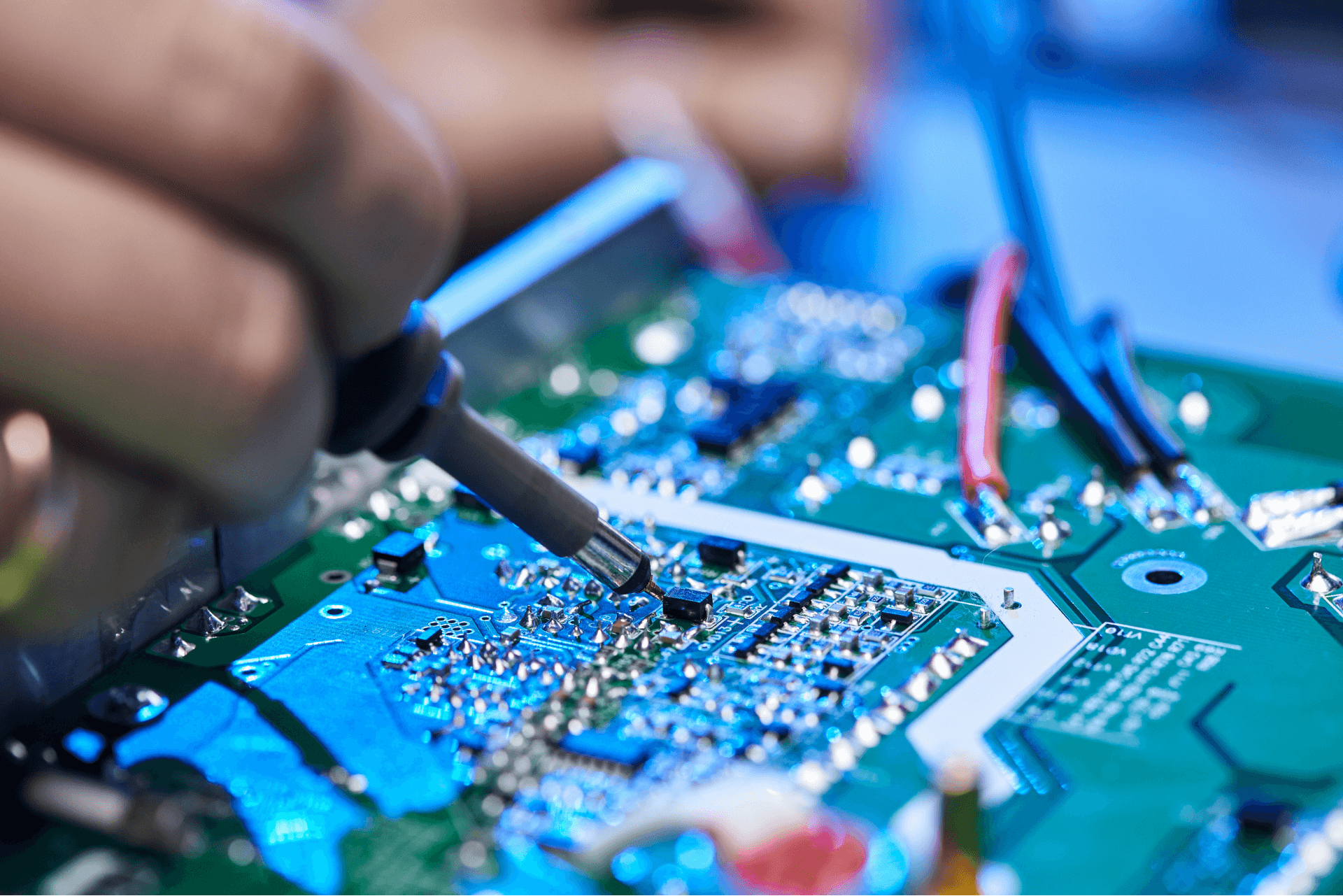

Precision and Adaptation: SolMotion Enhances Complex Assembly Processes

In complex industries like electronics and automotive assembly, the role of modern automation solutions is paramount in achieving the required flexibility. SolMotion‘s cutting-edge AI technology plays a vital role by effectively detecting randomly placed parts, regardless of their position, orientation, or appearance, eliminating the need for additional hardware fixtures. This remarkable capability is achieved through the comparison of high-quality 3D point clouds with trained golden samples. As a result, the system can precisely identify the location of the car door and its buttons, enabling the robot to adapt its motion path accordingly for efficient execution of quality checks.