SolMotion

Vision Guided Robotics

SolMotion Product Description

SolMotion merges advanced AI, 3D vision, and robotics, offering a versatile robotic solution for inspection, deburring, grinding, and polishing. SolMotion can learn to identify an object’s features from just a few images, enabling robots to adapt paths instantly without fixed positions, significantly reducing the need for costly fixtures. This flexibility is crucial for tasks involving diverse or evolving objects, streamlining operations, and cutting operational costs.

SolMotion Features

ROS-based automatic obstacle avoidance

Easy path editing, creation, and modification

Intuitive GUI for program logic editing

Flexible point cloud data editing (auto or manual)

Compatibility with 20+ global robot and PLC brands

Efficient project management and robot program backup

Automatic object recognition with path integration

Supports CAD/CAM software (remote programming)

SolMotion Benefits

Minimizes changeover time

Reduces fixture and storage costs

Lowers mechanical tooling expenses

Minimizes cumulative placement tolerance

SolMotion Functions

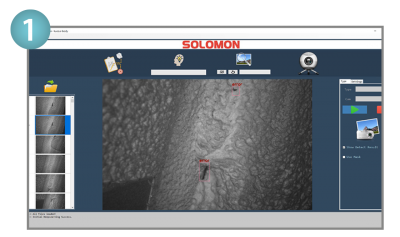

AI Deep Learning Tool

Neural networks train AI to recognize object features/defects on item surfaces. Unlike rule-based AOI, SolMotion’s AI inspection has broader, user-friendly applications without deep tech expertise. Paired with SolMotion’s vision-guided robot tech, a robot-mounted camera mimics human eyes, meticulously inspecting object surfaces.

Applications

- Painting defect and welding inspection

- Mold repair

- Metal defect inspection

- Food sorting

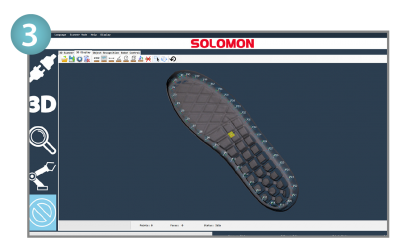

3D Vision Positioning System

Objects can be placed randomly without precise fixtures, thanks to SolMotion’s AI-driven visual recognition of distinct features that accurately pinpoints their spatial positioning for real-time robotic processing. Additionally, the system’s path-loading function, rooted in object feature recognition, enables flexible production.

Applications

- Various machine tending tasks

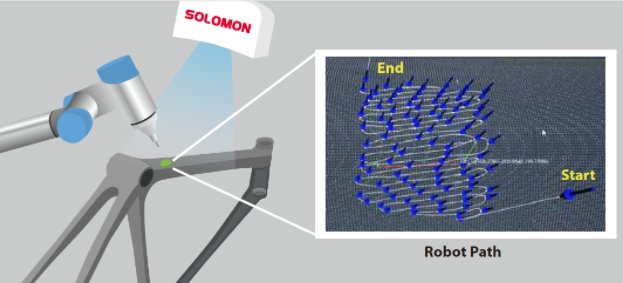

Robotic Path Planning Auto-Generation

No manual robot path setup is needed. Solomon’s AI learns environment edges for automatic path planning. Adjust processing angle as needed: “vertical” or a specific angle. Generate surface-filling paths, and optimize corner paths. Works with 20+ robot/PLC brands. Ideal for Hi-Mix/Low-Volume, variable path needs.

Applications

- Cutting

- Gluing

- Edge trimming

- Painting

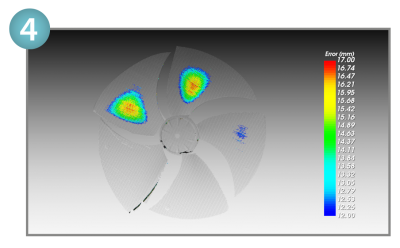

3D Matching Defect Inspection

SolMotion instantly compares real-time 3D point cloud data with the standard CAD. It creates a report based on the set difference threshold, showing height, width, and volume variations. This data can auto-generate robot paths. Ideal for object matching and deformation compensation tasks.

Applications

- Inspection

- Trimming

- Repairing

- Milling

- 3D Printing