SolMotionCase Study

Automotive Assembly Using Vision Guided Robotics + AI

Case

Car Door Electrics in Automotive Assembly

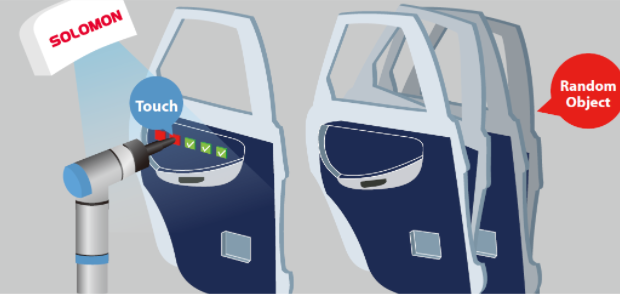

In automotive production, assembling various vehicle models on a single production line presents unique challenges, especially when it comes to ensuring the accurate functionality of critical components like car door electrics. For example, testing door buttons is essential to verify their performance. However, the different sizes and designs of car doors across models can cause positional shifts, leading traditional robotic systems to miss key quality checks. This underscores the need for more advanced solutions in automotive assembly to handle these variations with precision.

Challenge

Enhancing Flexibility and Precision in Automotive Assembly

As automotive manufacturers transition to producing multiple vehicle models on shared assembly lines, the limitations of traditional robotic systems become apparent. These systems are typically designed to handle fixed tasks with limited adaptability, requiring extensive reprogramming and mechanical adjustments when new models or component variations are introduced. This inflexibility leads to prolonged setup times, increased operational costs, and the risk of inconsistent quality checks. To meet the growing demand for faster production and diverse product lines, manufacturers need solutions that enable real-time adaptability without compromising precision.

Solution

Optimizing Automotive Assembly with Vision Guided Robotics and AI Technology

To tackle the challenges of flexibility and precision in automotive assembly, SolMotion offers an innovative solution that integrates vision guided robotics and advanced AI technology. This platform excels at detecting and identifying components, such as car door electrics, regardless of their position, orientation, or appearance on the assembly line. Utilizing high-resolution 3D point clouds compared to trained reference models, SolMotion accurately locates car doors and their buttons. This capability enables robots to adapt their motion paths in real time, streamlining the quality check process. By facilitating efficient handling of diverse vehicle designs, SolMotion significantly enhances productivity in automotive assembly operations.