3D Vision Picking Solution

What is 3D Vision Picking?

AccuPick 3D is a smart solution for bin picking that excels at picking random or unknown objects by using 3D machine vision to generate high-quality point clouds.

Building upon AccuPick 2D’s functionality and innovative design, AccuPick 3D can detect, pick, and place objects precisely regardless of their appearance, spatial location, or orientation, and can handle complex picking tasks including overlapping, irregular, and transparent or reflective objects.

Building upon AccuPick 2D’s functionality and innovative design, AccuPick 3D can detect, pick, and place objects precisely regardless of their appearance, spatial location, or orientation, and can handle complex picking tasks including overlapping, irregular, and transparent or reflective objects.

Benefits of 3D Vision

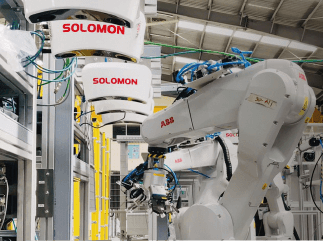

Solomon 3D Vision Picking Systems

What sets Solomon apart is the rapid AI model training embedded in our systems, allowing users to customize models with minimal time investment.

AccuPick Bin Picking

AccuPick 3D is a smart solution for bin picking that excels at picking random or unknown objects by using 3D machine vision to generate high-quality point clouds.

AccuPick Landmark

AccuPick LM is an innovative automation solution designed to optimize material handling and machine tending applications. With a focus on fast and accurate positioning, AccuPick LM enables efficient handling, tending, dispensing, and finishing operations without the need for structured light or 3D vision guidance.

Applications

Depalletizing