SolVisionCase Study

Gas Gauge Digitalization Using AI

Customer

The customer is an optoelectronics manufacturer specializing in the production of polarizers for high-precision displays. Maintaining consistent gas levels during the manufacturing process is crucial for achieving uniform film layers. The customer’s production process relies heavily on real-time monitoring of gas compression parameters, which directly impact product quality and yield.

Case

Gas Gauge Monitoring in Optoelectronics

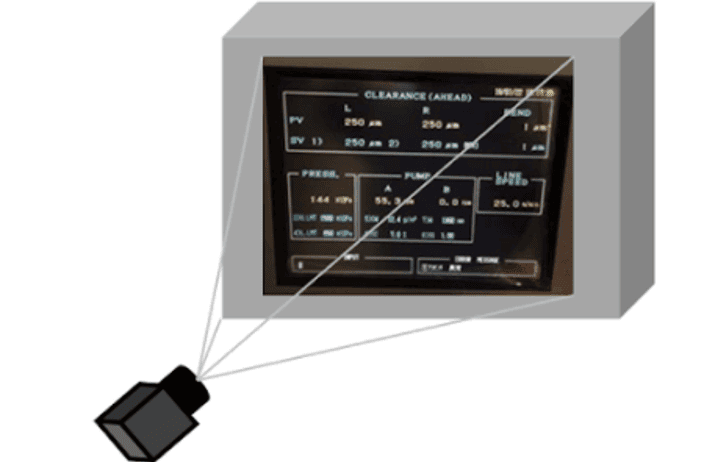

In the customer’s production line, precise gas levels are monitored using analog gas gauges. These gauges display critical information related to gas compression and other environmental parameters necessary for high-quality manufacturing. However, the lack of digital interfaces on these traditional gauges prevented the customer from quickly transferring the data into a digital monitoring system, slowing down decision-making and reducing operational efficiency.

Challenge

Manual Data Entry and Slow Response Times

The key challenge faced by the customer was the manual process of reading and recording data from analog gas gauges. This method introduced delays in the monitoring process and increased the likelihood of human error, making it difficult to respond quickly to fluctuations in gas levels. The absence of real-time digital data transfer also hindered the customer’s ability to optimize production processes and ensure the highest quality standards.

Solution

AI-Powered Gas Gauge Digitalization with SolVision

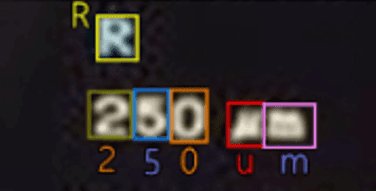

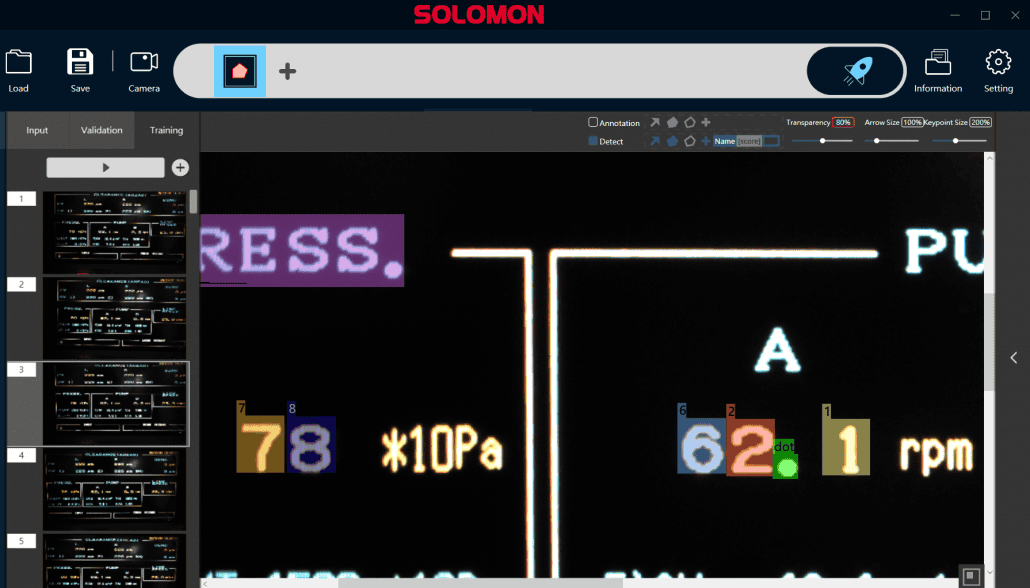

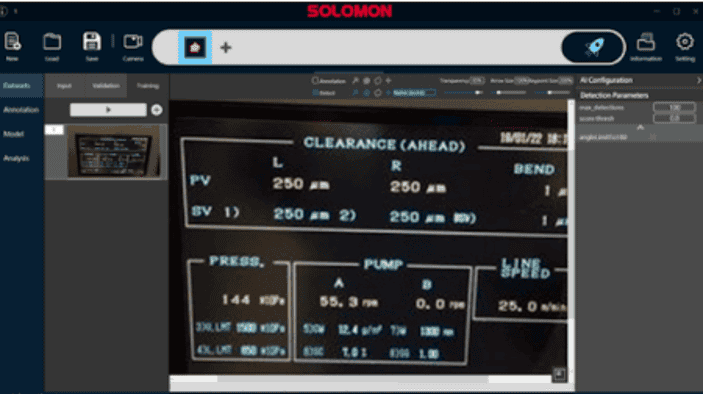

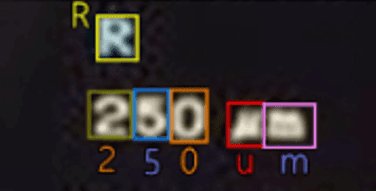

To address these challenges, the customer implemented SolVision, an AI-powered vision system. SolVision uses Optical Character Recognition (OCR) technology to convert the analog gauge readings into legible digital data. The system captures high-resolution images of the gas gauges and processes the information through AI-driven OCR. This digital data can then be uploaded into the customer’s monitoring platform, enabling real-time analysis and more efficient decision-making.

Gas Gauge Optical Character Recognition

Step 1: Camera captures images

Step 2: OCR extracts gauge data

Step 3: Data converted to digital format