SolVisionCase Study

Visual Inspection of Automotive Weld Beads

Detecting defects in random brightness conditions

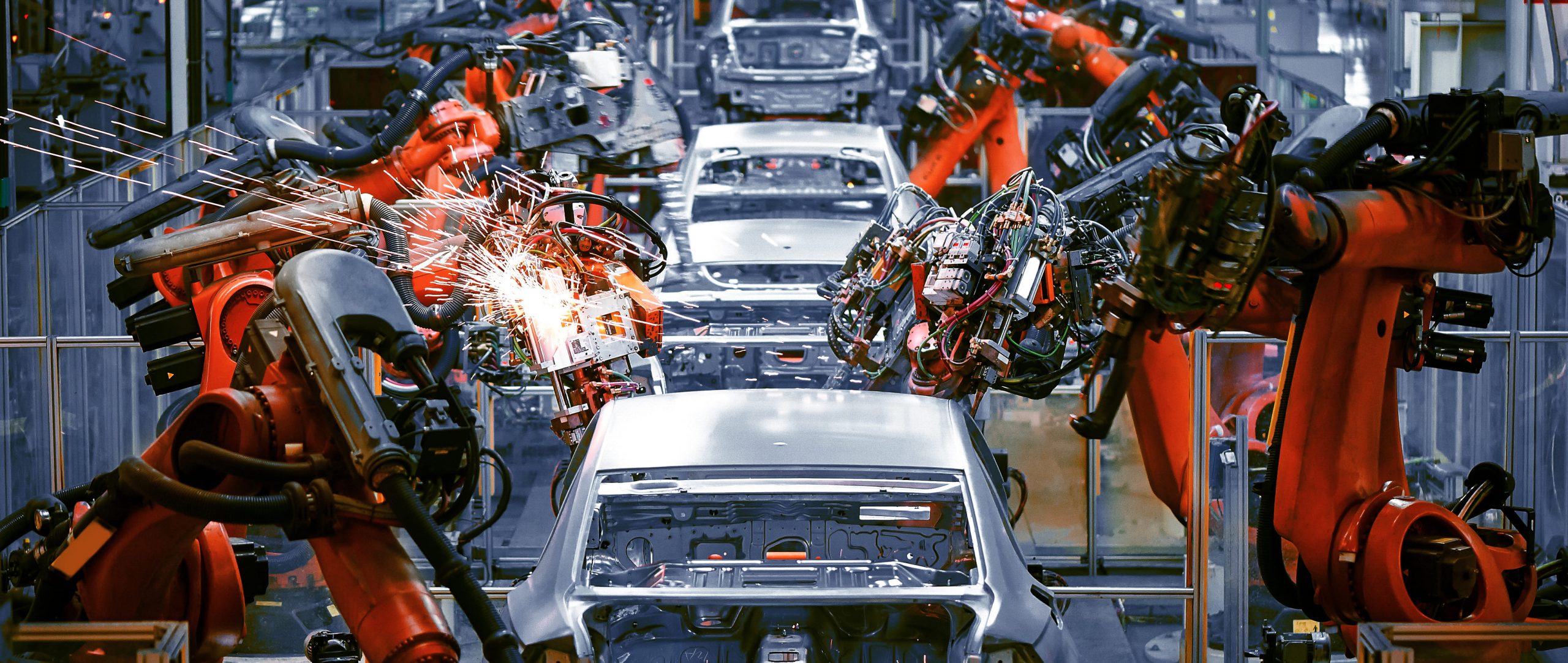

Welding of car body and structural quality

The structure of car bodies are complicated and made up of multiple stamped metal parts connected usually by welding, bonding, or riveting. Modern cars often use low-carbon steel plates, so welding is a common technique in the manufacturing process. During welding, the weld pool absorbs gas from internal reactions or external dissolution. Trapped gas sometimes cannot be discharged in time and remain in the weld bead, forming pores that affect the appearance and also structural quality of car bodies.

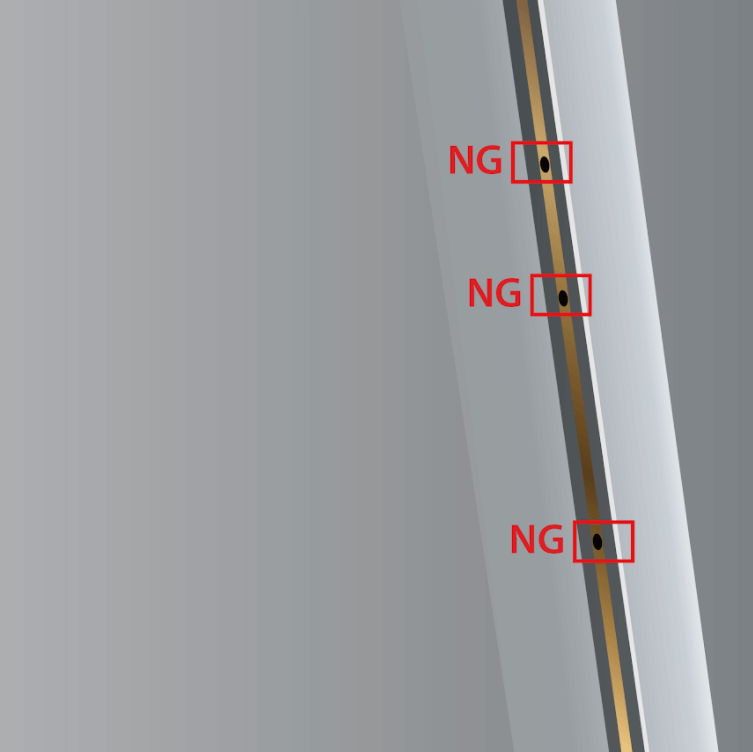

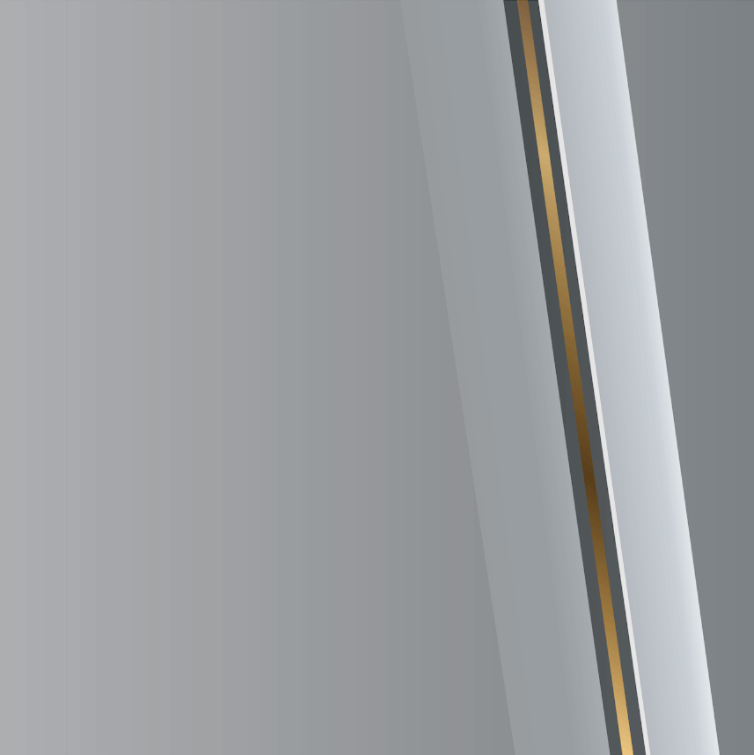

Brightness levels and images of weld bead porosity

Automobile roofs come in shapes that require weld beads in different heights, and so brightness conditions can vary when they are pictured. Randomly generated gas pores also have inconsistent appearances and characteristics, making it difficult to define rules for weld bead defect inspections.

Overcoming inconsistent brightness with SolVision

Powered by AI, SolVision can facilitate simulations of potential weld bead defects in different brightness to train the AI model, so that inspections of car bodies for weld defects are reliable and not constrained by brightness or lighting conditions.

AI Inspection

Golden Sample

Defective Weld Beads