SolVisionCase Study

IV Bag Classification Using AI

Case

Different Specifications of IV Fluids

IV fluids are available in various types, such as dextrose and sodium chloride, with concentrations and volumes that are tailored to specific medical needs. These fluids are typically stored in transparent drip bags, with details about their contents (including IV type, concentration, volume, etc.) printed on the exterior.

Challenge

Automating Inspection and Classification of IV Bag Labels

In IV fluid production lines, filled bags are commonly transported using the same conveyor system to the packaging area. Here, workers manually inspect and classify the bags based on their contents. However, due to the unpredictable placement of printed labels, traditional rule-based systems are unable to automate this process.

Solution

AI-Powered Feature Recognition

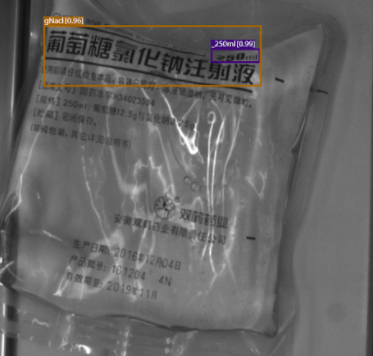

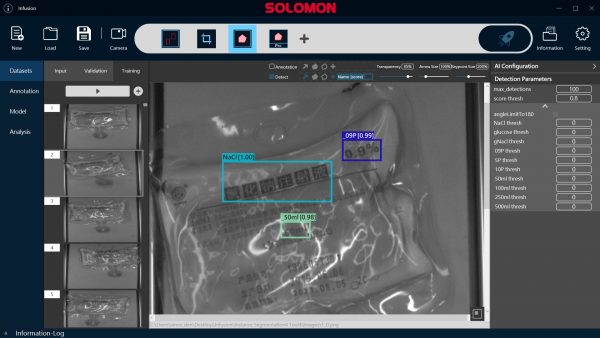

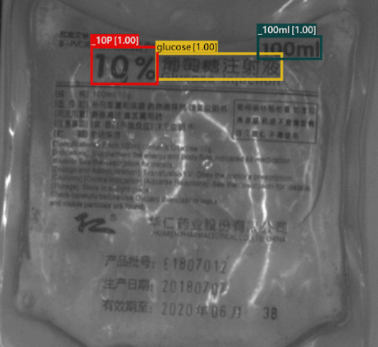

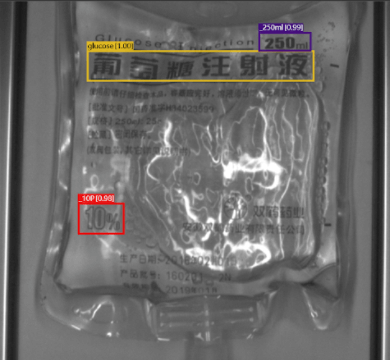

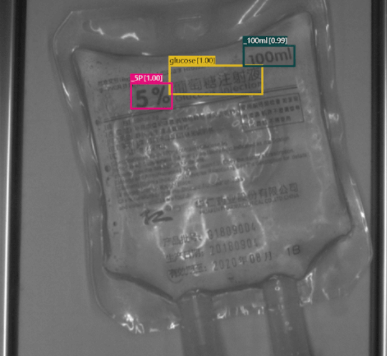

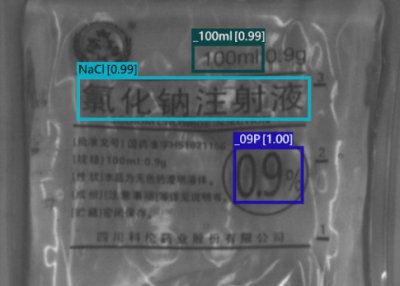

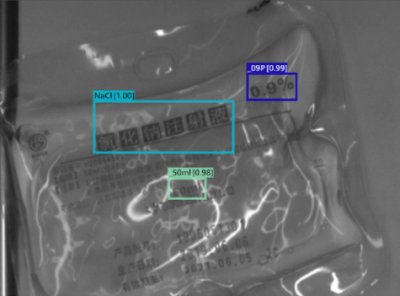

With SolVision‘s segmentation tool, various labels can be identified from sample images to train a visual inspection system capable of classifying information on IV bags based on their distinctive features. SolVision’s advanced AI-based technology is also unaffected by transparent objects, label complexity, or appearance.

Classification

Dextrose Solution

Sodium Chloride Solution

Glucose and Sodium Chloride Solution