SolVisionCase Study

Bottle Cap Inspection Using OCR

Case

Product Labeling Requirements

Challenge

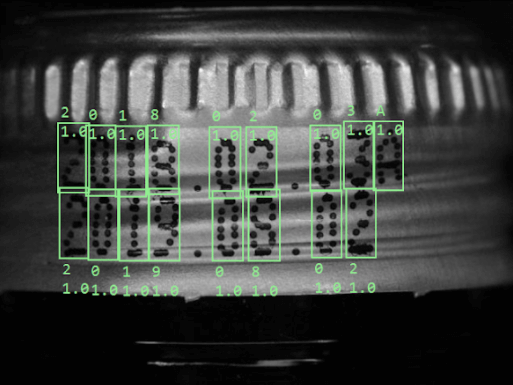

Date and Batch Code Recognition on Aluminum Bottle Caps

Consumer beverages commonly utilize glass bottles with aluminum caps for packaging. Production and storage dates are typically printed on the side of the cap, while the batch barcode is located on the bottle. The metallic luster and spiral pattern of aluminum caps pose challenges for traditional character recognition, making printed text hard to detect. Moreover, the high-speed nature of beverage production lines further complicates the accurate reading of printed information.

Solution

Enhanced Production Line Inspection with SolVision

SolVision offers a fully automated visual inspection solution, implementing Optical Character Recognition (OCR) through the development of an AI model using sample images of production information. Leveraging advanced image processing capabilities, the software excels in matching the pace of fast production lines, recognizing dates and barcodes even in cases of poor printing. The system can additionally identify defective labels and misprinted information, contributing to enhanced inventory management and tracking capabilities.

Bottle Cap Optical Character Recognition

OK

NG

Bottle Cap Defect Detection

Missing Text

Smudged Text

Skewed Text