AccuPick 3DSmart Bin Picking

Industrial Automation Software

AccuPick 3D Product Description

AccuPick transforms robotic material handling with its innovative few-shot learning AI, which swiftly and accurately identifies thousands of SKUs with minimal learning time, even for specific picking points or orientations. This efficiency establishes AccuPick as the trusted solution for managing the diverse array of products in modern warehouses and logistics centers, enhancing operational workflows and overall efficiency.

AccuPick 3D Features

Compatible open platform

Graphic-based interface

Industry leading AI and 3D vision

Collision-free motion planning

Auto labeling

No more CAD files

AccuPick 3D Compatibility

Open platform compatible with over 20 robot brands

What is Material Handling with 3D Vision?

Solomon’s 3D vision systems tackle the constraints of traditional robots by providing them with ‘eyes’ (vision), while AI serves as their ‘brain’ (intelligence). With these human-like perception abilities, robots can now accomplish intricate tasks that were once beyond automation within factories and warehouses.

Logistics and Warehousing

E-commerce

Packaging

Food and Beverage

Automated Bin Picking Random or Complex Objects

AccuPick 3D utilizes AI image processing to overcome difficulties that regular vision systems encounter, especially when dealing with object shape, material, or size.

Soft or deformable objects

Transparent or reflective objects

Irregular objects with holes, protrusions, etc.

Complex patterns or backgrounds

Small, thin objects up to 0.5 mm

Overlapping objects

AccuPick 3D Case Studies

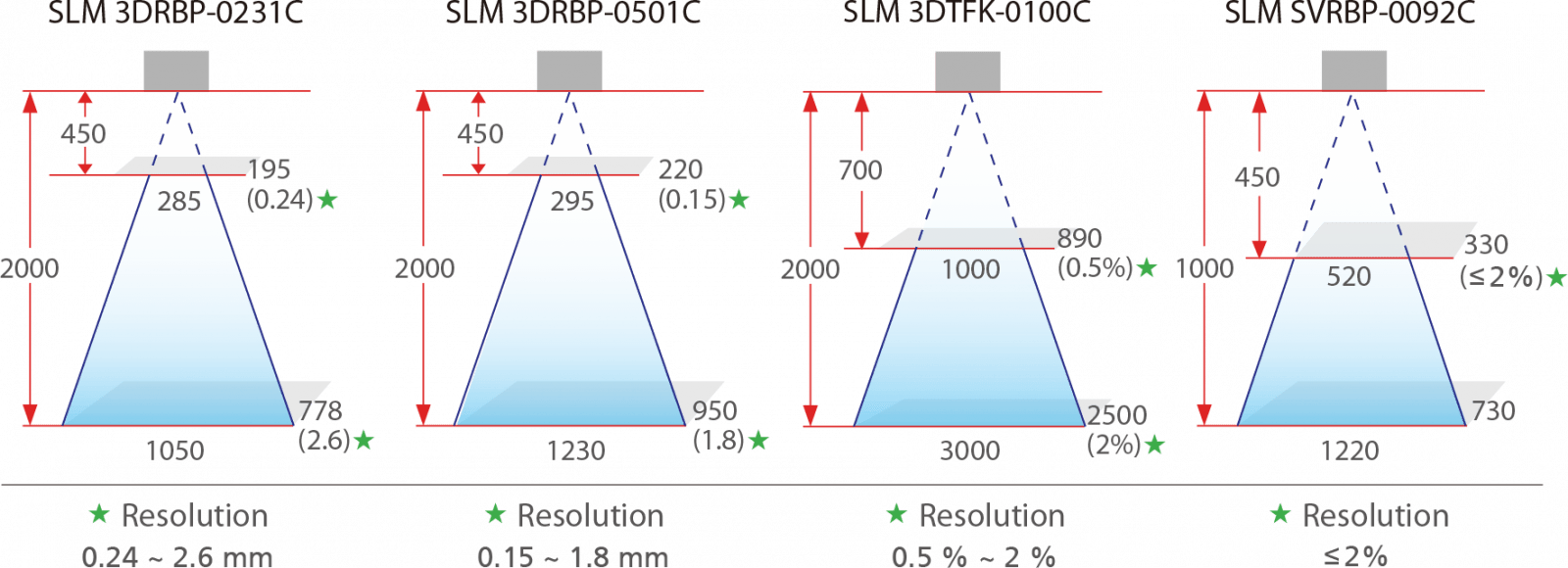

3D Scanner Field of View (FOV)