AccuPickCase Study

Automated Packing Using AI

Customer

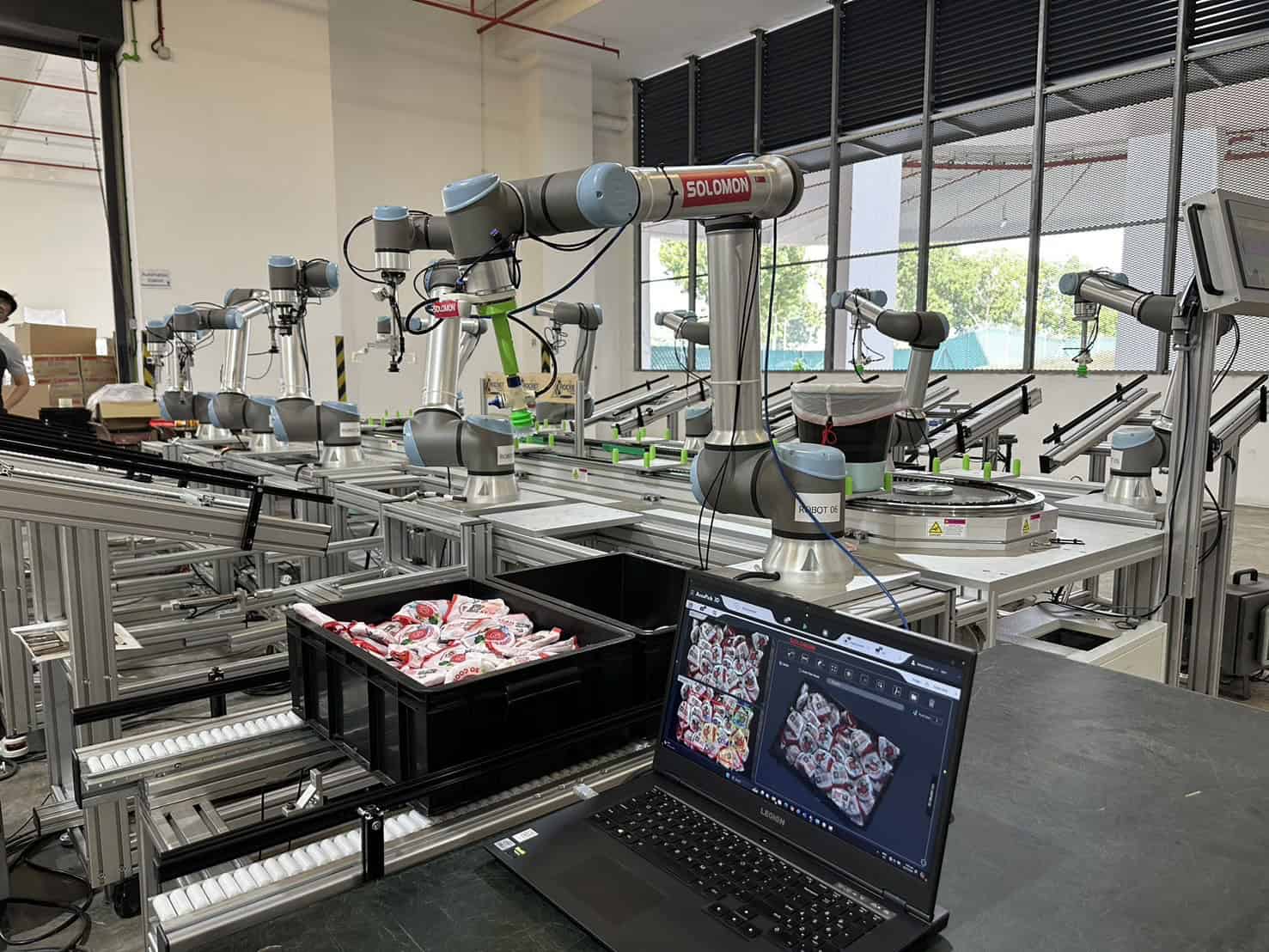

Solomon partnered with the Singapore Army and the Singapore National Day Parade (NDP) committee to automate the packing of NDP packs (goodie bags) distributed at the parade. In collaboration with Universal Robots, Zimmer Group, and Pocket Technology Pte Ltd, the project aimed to enhance the efficiency and accuracy of the packing process.

Case

Enhancing Efficiency for Singapore’s National Day Preparations

The objective was to develop an automated packing line to handle the high-volume assembly of 300,000 NDP packs, ensuring timely preparation and distribution for Singapore’s National Day celebrations. This pilot project aimed not only to address packing challenges but also to explore future automation in other logistics operations across Singapore.

Challenge

Overcoming Manual Packing Limitations

Traditionally, NDP packs were packed manually by military personnel. The Singapore Army sought to transition to automation to improve efficiency and accuracy. Each NDP pack needs to contain a specific set of items, with each pack requiring exactly one of each item. The challenge was compounded by the fact that items are randomly arranged and often overlapped, making it difficult for ordinary picking systems to handle.

Solution

Automated Packing Made Easy with Precision Bin Picking

The automated packing line utilized Solomon’s AccuPick bin picking software, which employs 3D vision technology to pick and place items into NDP packs without programming. AccuPick requires only a few image samples to train the AI model, allowing for rapid adaptation to varying item arrangements. The system, featuring ten UR cobots working in tandem, efficiently managed items that were randomly stacked in bins. Enhanced by AI vision cameras, AccuPick provided precise item recognition and sorting. This automation of the packing process reduced manpower needs by 50%.