AccuPickCase Study

Car Door Assembly Inspection Using AI

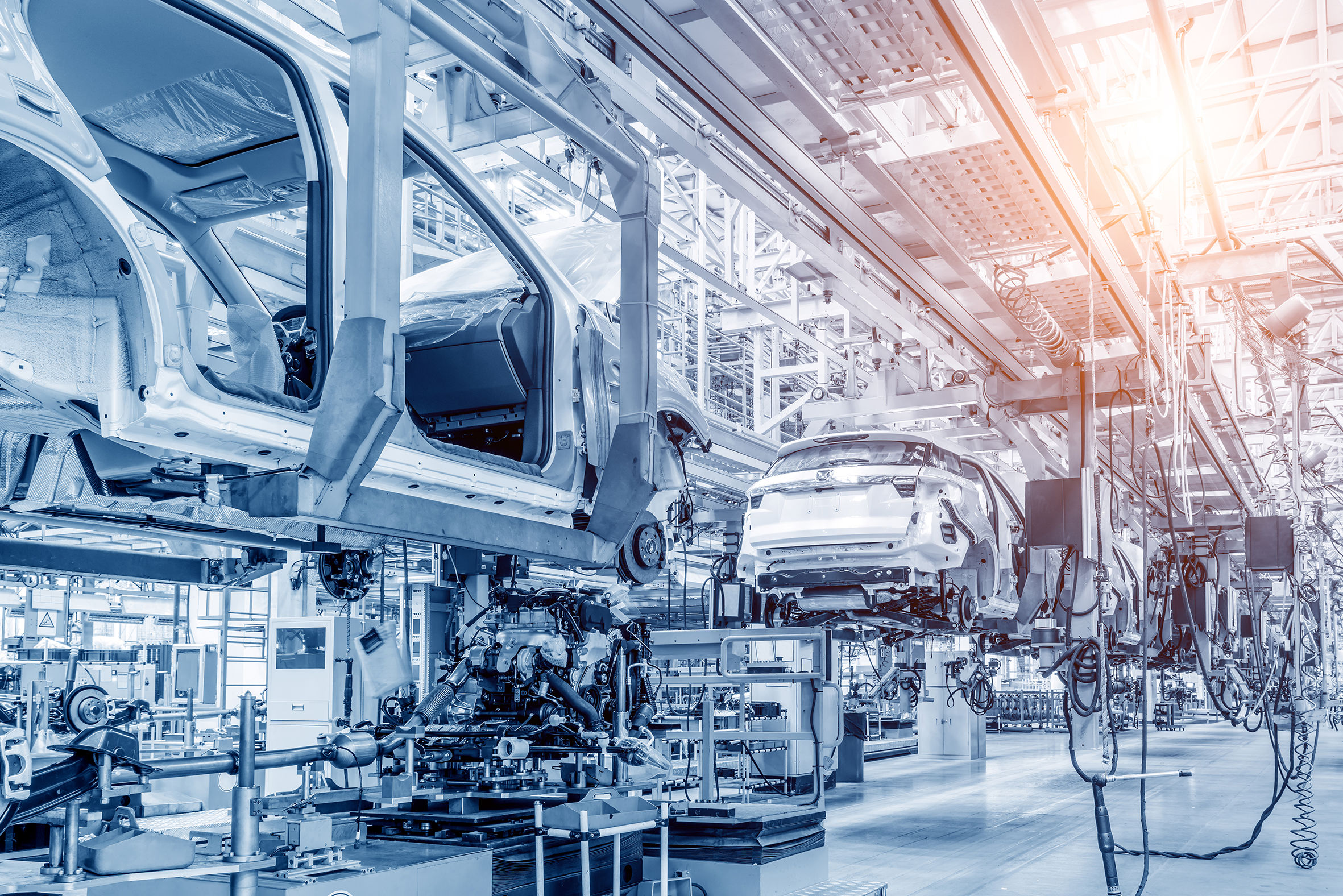

Case

Quality Testing for Automotive Door Assembly Lines

Car door buttons are vital in the manufacturing and assembly of vehicles. Despite their small size, these buttons directly control various car systems like power windows, central locking, anti-theft features, and seat adjustments. Their proper operation is crucial for the overall performance and safety of the vehicle. Consistency in button appearance is also important for upholding the vehicle’s exterior quality perception, which significantly impacts overall quality and customer satisfaction.

Challenge

Addressing the Complexity of Door Button Inspection

As doors move along the assembly line, workers install buttons in sequence. Post-installation, various tests like functional, lifespan, electronic, durability, and visual inspections ensure each button meets quality standards. However, differences in button designs across car models require manual and computational testing for smooth operation. Continuous testing can lead to human fatigue, affecting inspection accuracy and efficiency.

Solution

Enhancing Automation Efficiency with AccuPick + SolVision

Utilizing the AccuPick intelligent handling system and robotic arms for accurately positioning door buttons using 3D visual judgment ensures precise pressing tests, including latch engagement, meeting the high-speed processing demands of the assembly line. Additionally, the assembly line is equipped with the SolVision AI vision inspection system, which employs advanced neural networks to detect irregularities, classify objects, and ensure the completeness of components such as central locks, window switches, and mirrors.