SolVisionCase Study

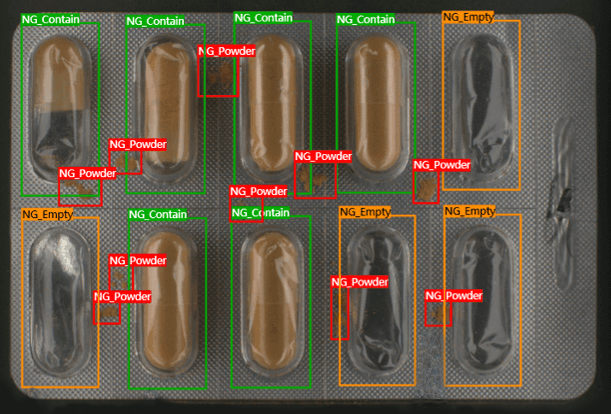

Blister Pack Inspection Using AI

Case

Inspecting Pharmaceutical Blister Packaging

Blister packaging, or push-through-package (PTP), is commonly used for tablets and capsules to prevent moisture damage and allow for convenient consumption. It typically includes transparent PVC, an aluminum foil back layer, and PVDC sheets to reduce permeability. PTP production lines pack 5,000-40,000 tablets/capsules per hour but may experience occasional filling errors, ranging from unfilled blisters to tablet/capsule issues. Addressing these errors is vital for pharmaceutical packaging reliability.

Challenge

Inspecting Reflective Materials on Fast-Moving Production Lines

Historically, PTP production depended on manual or traditional inspection methods for verifying packaging quality and identifying filling errors. However, the susceptibility of PVC to light reflection posed challenges in accurate inspection along accelerated production lines. This limitation resulted in elevated rates of defective products.

Solution

Deep Learning AI Inspection with SolVision

SolVision offers an AI solution where images of high-quality PTP samples and various defects can train an AI model for automated visual inspection. The machine vision system’s Segmentation tool precisely detects each blister and its contents, enabling accurate identification and classification of defects to streamline subsequent production processes.