SolVision成功案例

食品加工产线输送带瑕疵检测解决方案

自动化食品生产线搭配AI瑕疵检测

食安守门员:AI外观检测与监控,挑出不良品

食品加工业首重食品卫生及食用安全,加工过程中品保(Quality Assurance, QA)与品管(Quality Control, QC)是产品高品质与高水准的关键。在快速且大量生产的食品产线中,外观检测是把守品质的最重要防线。

智慧化食品加工产线:减少人力浪费

油炸食品的外观不一,在食品加工输送带上呈随机排列。传统的食品外观检测透过大量人力执行,效率不彰。产线上过多的人力亦造成环境卫生控管疑虑。未数位化、智慧化的产线,亦无法透过产品监控达到产品瑕疵溯源的效果。

肉品龙头品质的自信根据:AI瑕疵检测

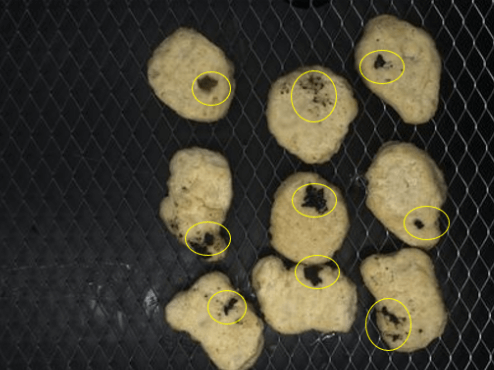

所罗门结合机器视觉与人工智能,运用 SolVision AI影像平台的实例切割技术执行缺陷检测(Defect Detection)。在快速且大量生产的油炸食品加工产线中,辨识多种不同的瑕疵样态,进而将不良品即时检出。

缺陷检测结果

黑色油屑

褐色油屑

交叠相连

深色表面