Bin Picking Steel Parts Using AI

Case Overview

Customer: Motion Technique (systems integrator for Siemens)

Location: India

Industry: Electronics / Smart Manufacturing

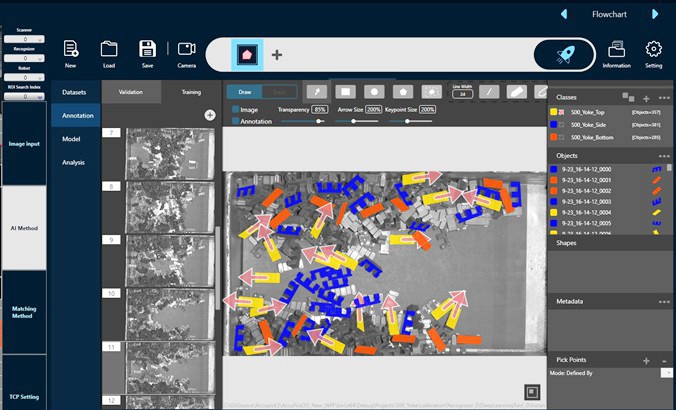

Solution: AccuPick

Objectives:

- Achieve accurate recognition of laminated steel component position/orientation

- Enable collision-free bin picking in deep containers

- Meet strict cycle time requirements for switchgear manufacturing

Results:

- 100% collision-free picking with long gripper in deep bin

- Achieved 6-second cycle time for pick-and-place

- Improved accuracy in component orientation recognition

Testimonial:

“We are glad that we chose AccuPick for one of the most challenging bin picking projects that came our way. We believe no other bin picking solution would have been able to execute this project of such high complexity.”

Uday Mali, Director, Motion Technique

The Customer

Motion Technique, a systems integrator based in India, partnered with Solomon to enhance automation at Siemens’ switchgear manufacturing facility. Siemens, a global leader in electrical engineering and manufacturing, required a highly precise and efficient bin picking solution to handle complex laminated steel components in their production process.

The Challenge

Overcoming Precision and Collision Risks in Production

Siemens needed a reliable way to pick small, heavy laminated steel components from deep bins without collisions, while meeting strict cycle time requirements. The parts’ complex shapes, random orientations, and tendency to tangle made CAD-based localization ineffective, creating risks to productivity, quality, and operational efficiency.

The Solution

Customised Automation for Complex Part Handling

To address component picking challenges from deep bins, Motion Technique deployed Solomon’s AccuPick AI-based bin picking system together with a SolScan 2.3 MP scanner, integrated with a Universal Robots UR10 cobot. This setup enabled precise orientation detection, collision-free operation, and seamless component placement via a custom slider, fully meeting Siemens’ accuracy and speed requirements.