SolVisionCase Study

Ribbon Fabric Inspection Using AI

Case

Ribbon Fabric Quality Control

Ribbons come in many varieties, from color and size to styling and fabric type. The production process is intricate, requiring delicate handling and multiple steps, including warping, threading, weaving, ironing, dyeing, finishing, printing, sewing, tape winding, and, crucially, quality inspection and packaging. Given the high stakes involved in textiles quality control, effective defect detection is essential to ensure that only superior ribbons reach the market, safeguarding brand reputation and compliance with industry standards.

Challenge

Limitations of Traditional Inspection Systems

The wide variety of ribbons presents significant challenges for traditional rule-based vision systems, which offer limited flexibility in adapting to diverse textures, patterns, and colors. The intricate designs and unique features of ribbon fabric make it difficult for conventional vision inspections to accurately detect defects. As a result, these systems are highly prone to errors and missed inspections, compromising textiles quality control and increasing the risk of delivering subpar products to the market. This underscores the need for a more advanced solution that leverages AI for effective defect detection in the ribbon manufacturing process.

Solution

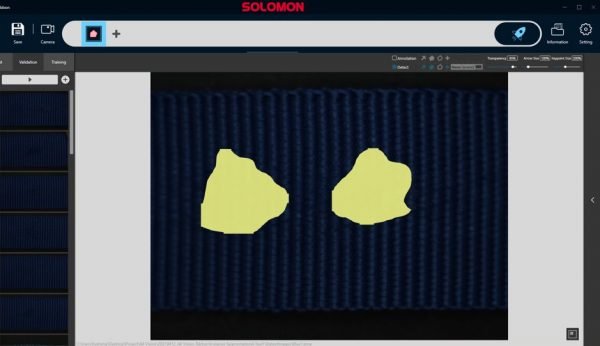

AI-Driven Defect Detection for Ribbon Fabric Inspection

SolVision enhances ribbon fabric inspection by employing AI-powered defect detection. Utilizing advanced AI segmentation tools, the system inspects a diverse range of colored and patterned ribbons, accurately identifying defects of various types and sizes. This approach streamlines the inspection process, reducing the time required for quality control while capturing and analyzing defect data. By allowing textile manufacturers to trace production issues, SolVision ensures that only high-quality ribbon fabric meets market standards, reinforcing overall quality control and maintaining brand integrity.

Ribbon Fabric Defect Detection

Hole

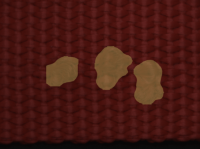

Knots

Broken Stitch