SolVisionCase Study

Yarn Inspection Using AI

Case

Quality Control in Yarn Production

Effective yarn inspection is crucial for identifying defects early in the manufacturing process, helping to preserve product quality and minimize waste. As demand for high-quality yarn rises, textile producers must implement robust quality control measures to meet industry expectations and enhance operational efficiency.

Challenge

Limitations of Traditional Inspection Methods

Conventional yarn inspection methods often rely on manual processes, which are not only time-consuming but also prone to human error. Defects in yarn, including stains, deformation, knots, broken fibers, splitting, fuzzy edges, and incorrect colors, complicate quality control. These variations make it difficult to ensure thorough inspections. Additionally, traditional rule-based vision systems struggle with irregular yarn defects and high volumes, resulting in inaccurate detections that require time-consuming manual verification. To enhance productivity and quality in the textiles industry, a more effective and dependable inspection solution is essential.

Solution

Detecting Yarn Defects with SolVision

SolVision employs advanced AI technology to enhance yarn inspection by accurately detecting various yarn defects through image analysis. The system identifies common issues such as knots, stains, and irregularities quickly, improving detection rates and production efficiency while reducing the reliance on manual checks. This automation minimizes human error and ensures consistent quality control. As the volume of inspection data increases, the AI model continuously adapts and refines its algorithms, facilitating effective integration across multiple production lines and helping manufacturers maintain high-quality standards.

Yarn Defect Detection

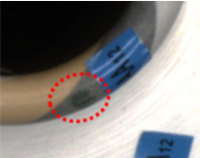

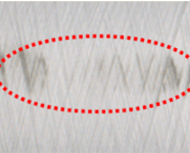

Stain

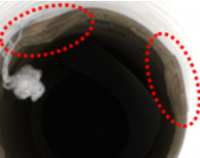

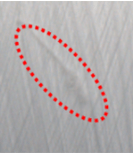

Damage

Damage

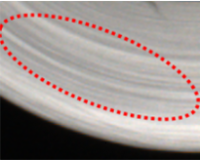

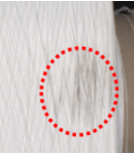

Distortion

Stain

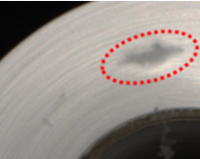

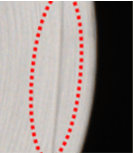

Scratch

Damage

Distortion