SolVisionCase Study

Carbon Fiber Fabric Defect Detection Using AI

Customer

The client, a systems integrator (SI), is working with a carbon fiber fabric manufacturer to implement an advanced defect detection system.

Case

Ensuring Quality in Carbon Fiber Fabric

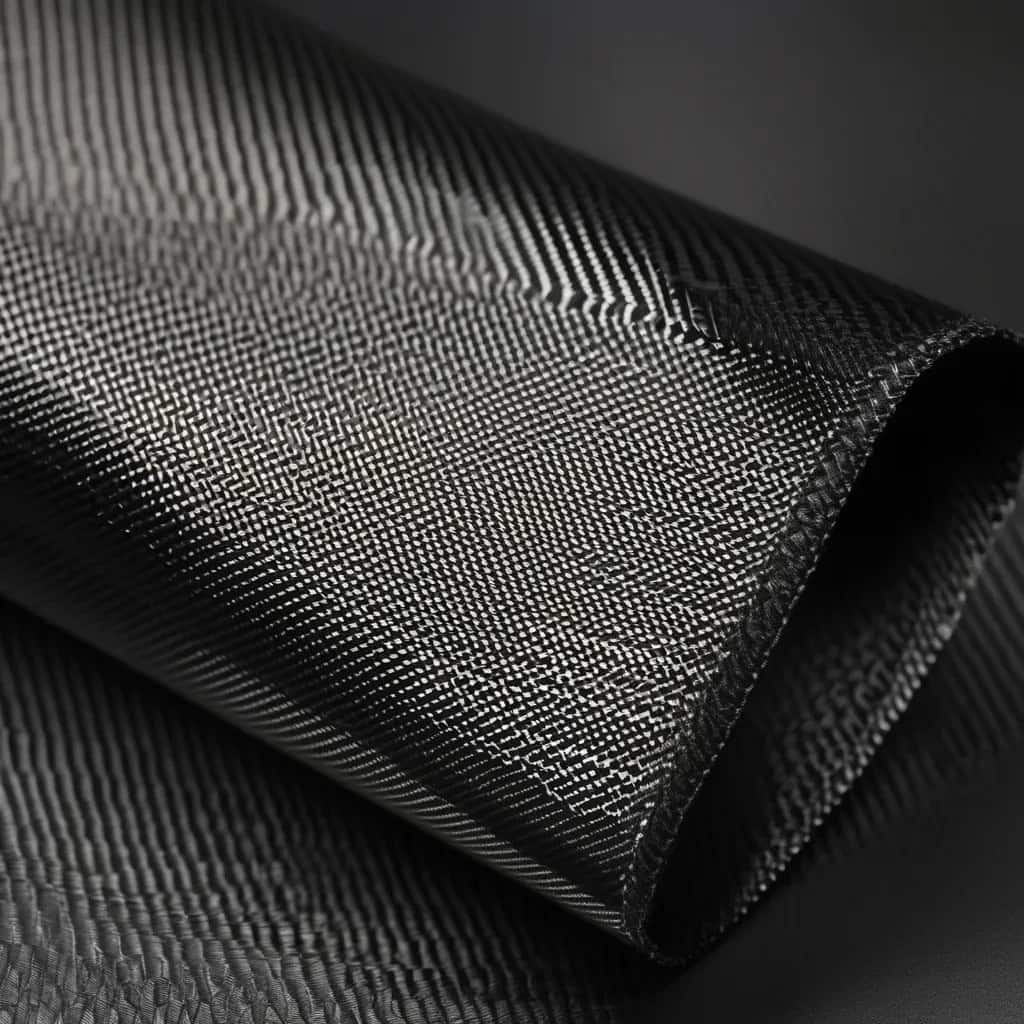

Carbon fiber is a high-performance material known for its lightweight, high strength, high elastic modulus, and resistance to temperature, acids, and fatigue. Its chemical inertness and strong conductivity make it valuable in automotive, aerospace, shipbuilding, industrial applications, and structural reinforcement. Effective defect detection is essential to ensure the quality and performance of carbon fiber components.

Challenge

Detecting Carbon Fiber Fabric Defects

Detecting defects in carbon fiber fabric is challenging due to its softness and the subtlety of potential marks, which can be hard to see with the naked eye. Variations in lighting and inspection angles further complicate traditional methods, often leading to missed defects and unreliable inspections.

Solution

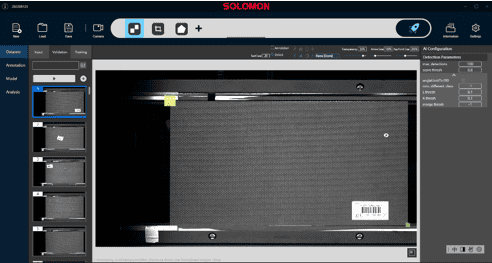

Enhanced Defect Detection with AI

SolVision offers an effective solution for identifying defects that are not visible to the naked eye. Utilizing advanced AI vision inspection technology, SolVision analyzes a range of defect samples and adjusts for variations in lighting and angles. This approach enhances the accuracy of defect detection and improves quality control in the manufacturing process.

Carbon Fiber Fabric Defect Detection

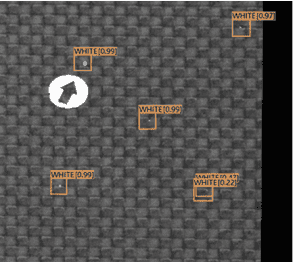

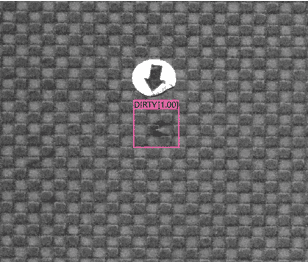

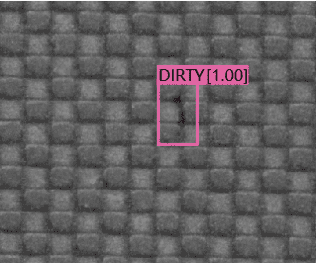

Spots

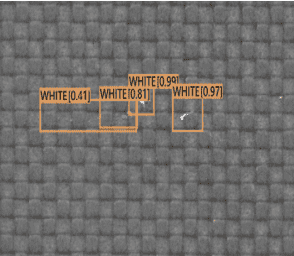

Stains

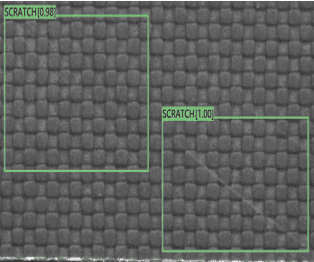

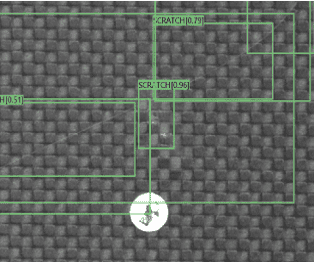

Scratches