SolVisionCase Study

Metal Casing Quality Inspection Using AI

Case

Hardware Casing Quality Control

To maintain consistent quality, consumer electronics like PCs and other devices require a meticulous inspection of their hardware casings before final assembly.

Challenge

Difficulties Inspecting Reflective Surfaces

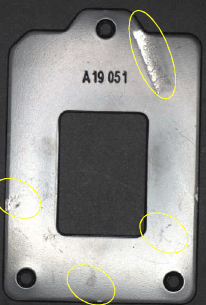

Detecting subtle defects and scratches on reflective metal surfaces is a major challenge for quality control. Because these flaws are often barely visible to the human eye, manual inspection is difficult and prone to high error rates. This poses a significant risk to production efficiency and product quality.

Solution

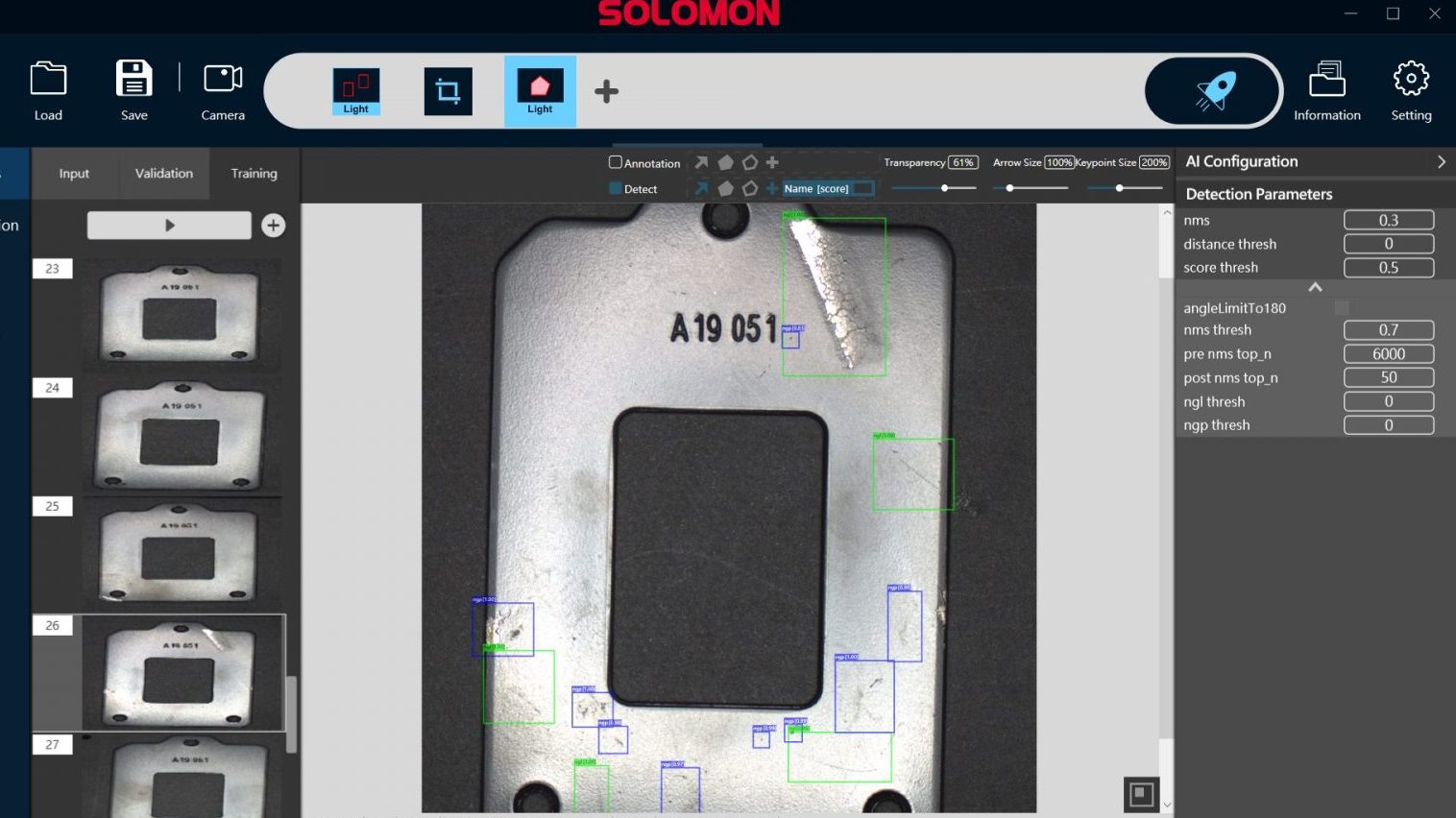

SolVision AI Vision System for Automated Inspection

With its advanced segmentation tools and powerful deep learning capabilities, the SolVision AI vision system can be trained to identify and categorize a wide range of defects based on their unique features. It creates a customizable database that classifies defects into distinct groups, such as obvious defects, minor defects, and micro defects. This system enhances the accuracy and efficiency of metal casing quality inspections, ultimately ensuring that defective products are stopped before they can disrupt the assembly process.

Metal Casing Defect Classification

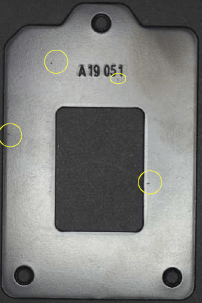

Micro Defects

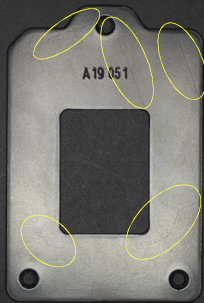

Minor Defects

Obvious Defects