SolVisionCase Study

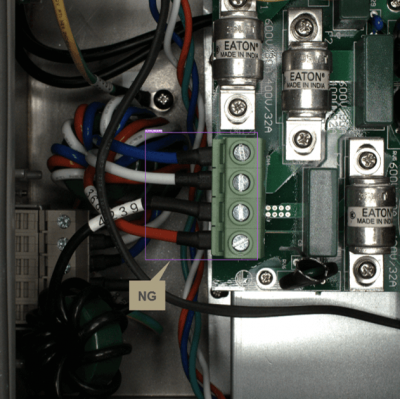

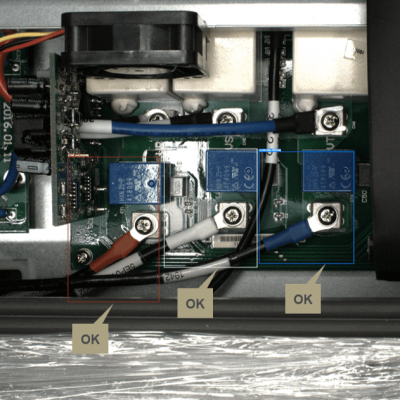

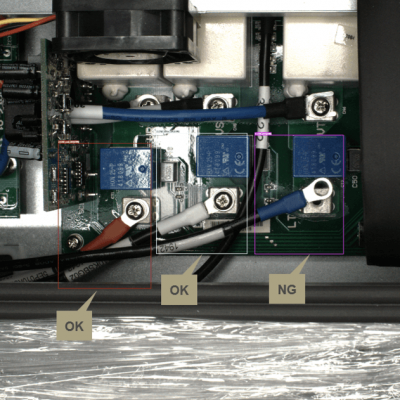

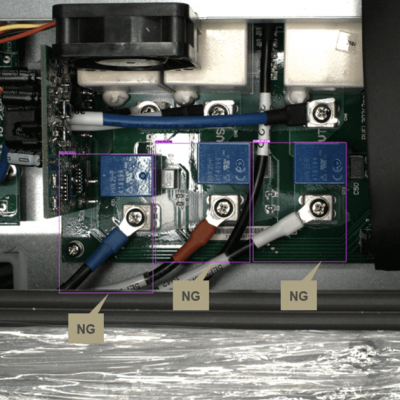

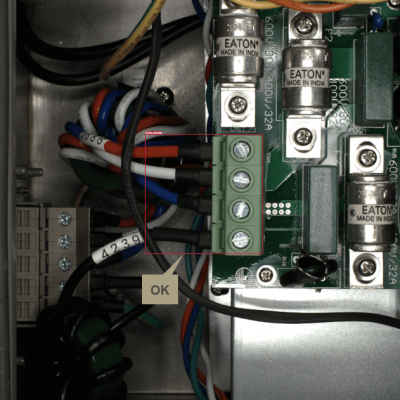

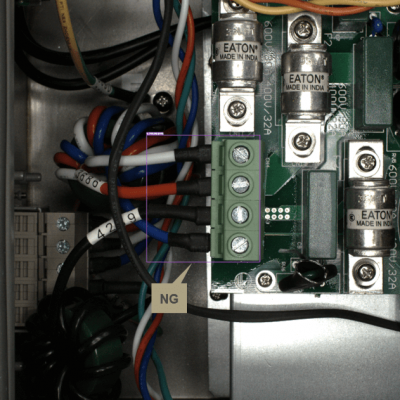

AI Inspection of Power Supply Unit Cables

Inspection of hard drive metal base components

Cables for electrical and signal transmission

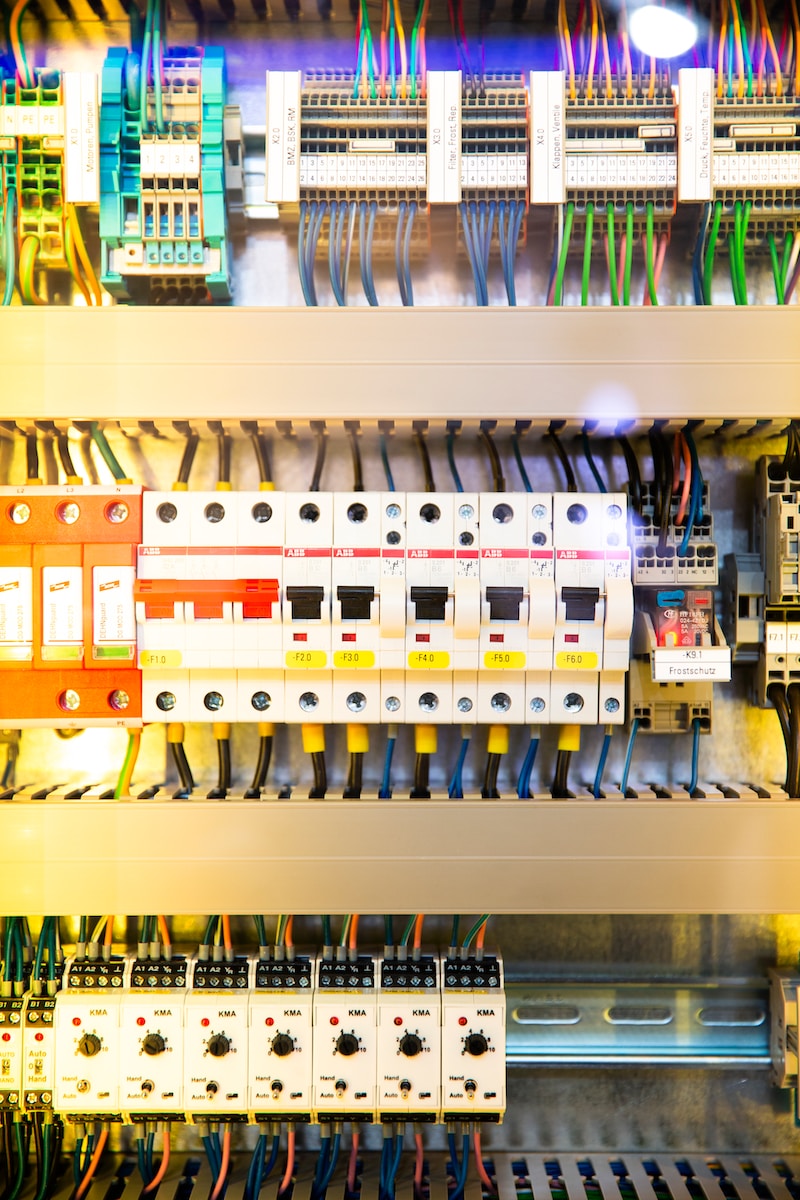

Power supply units (PSUs) such as rectifiers, inverters, and transformers are used to convert electric power from a source to another device. They are made up of different components such as controls, adjusters, and auxiliary circuits, which are sometimes connected incorrectly during assembly.

Background interference during inspection

Internal components and circuits of power supply units are diverse and complex, creating backgrounds that require advanced recognition capabilities to analyze. Cables are also easily deformable, and depending on the assembler can be arranged or stored differently. These uncertainties make it difficult to implement product quality control with manual and rule-based inspections.

AI Visual Inspection

SolVision’s segmentation tool can train the AI model to recognize different types of defects based on the shape of the metal base. Regardless of the size, appearance, or variations of defects, the system can identify them quickly and accurately to maximize production throughput.

AI Inspection

Wiring sequence: red-white-blue

Missing Screw

Incorrect Sequence

Wiring sequence: red-white-blue-black

Incorrect Sequence

Incorrect Sequence