SolVision

AI Vision SystemVisual Inspection Software

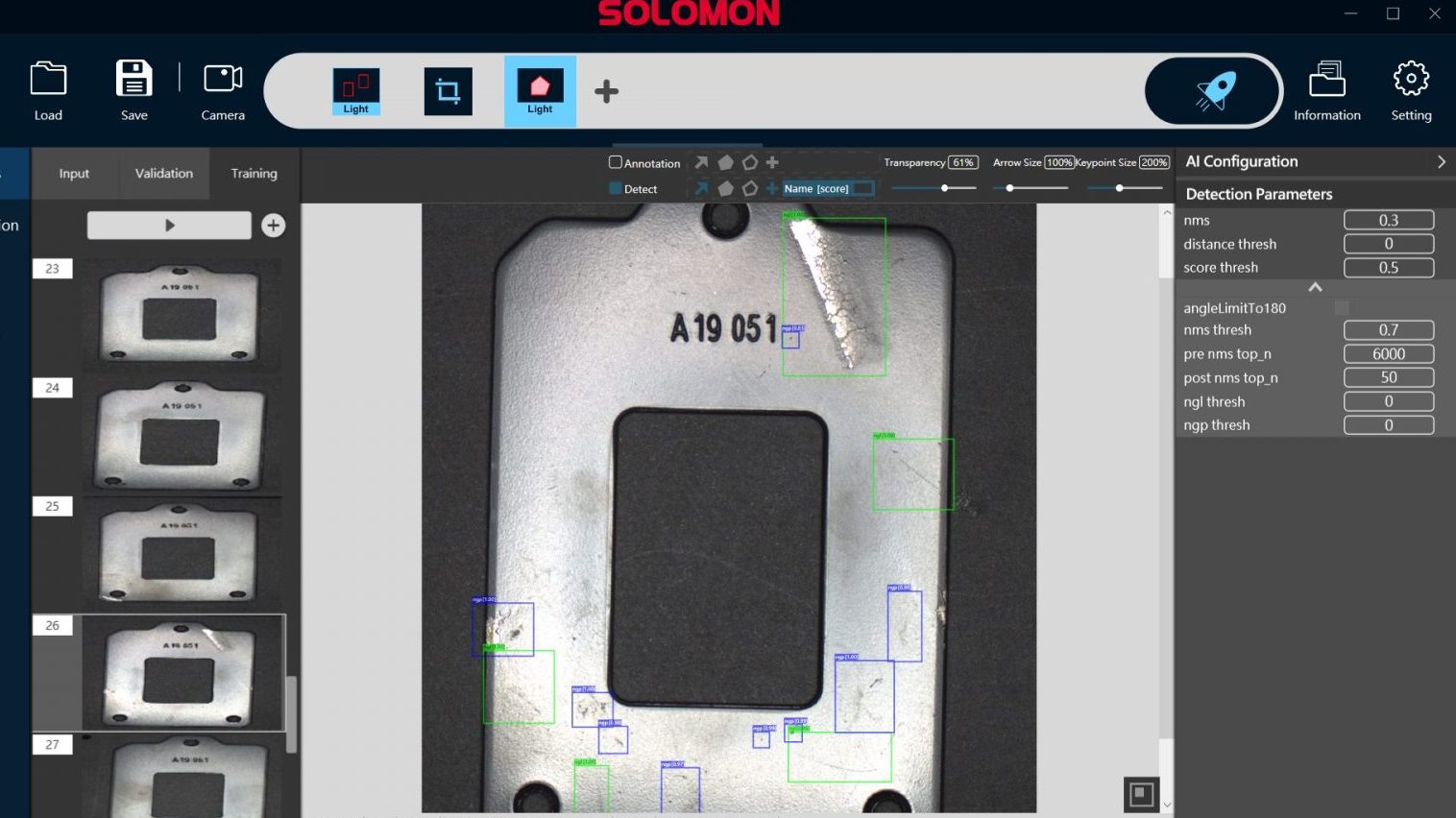

SolVision AI vision system software optimizes visual inspection with Solomon’s unique rapid AI model training, enabling fast and accurate defect detection, item classification, presence/absence detection, optical character recognition (OCR), and quality inspection.

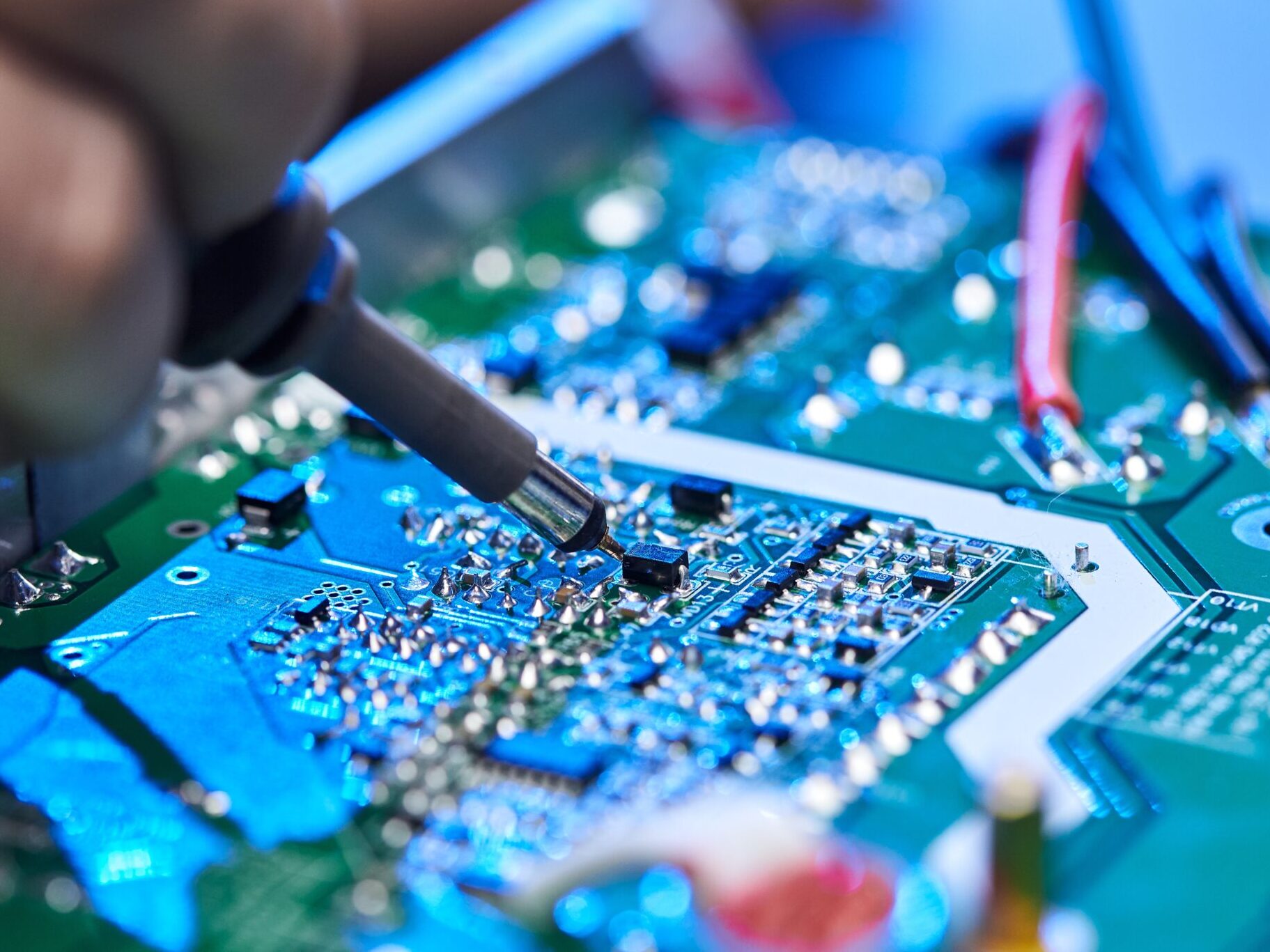

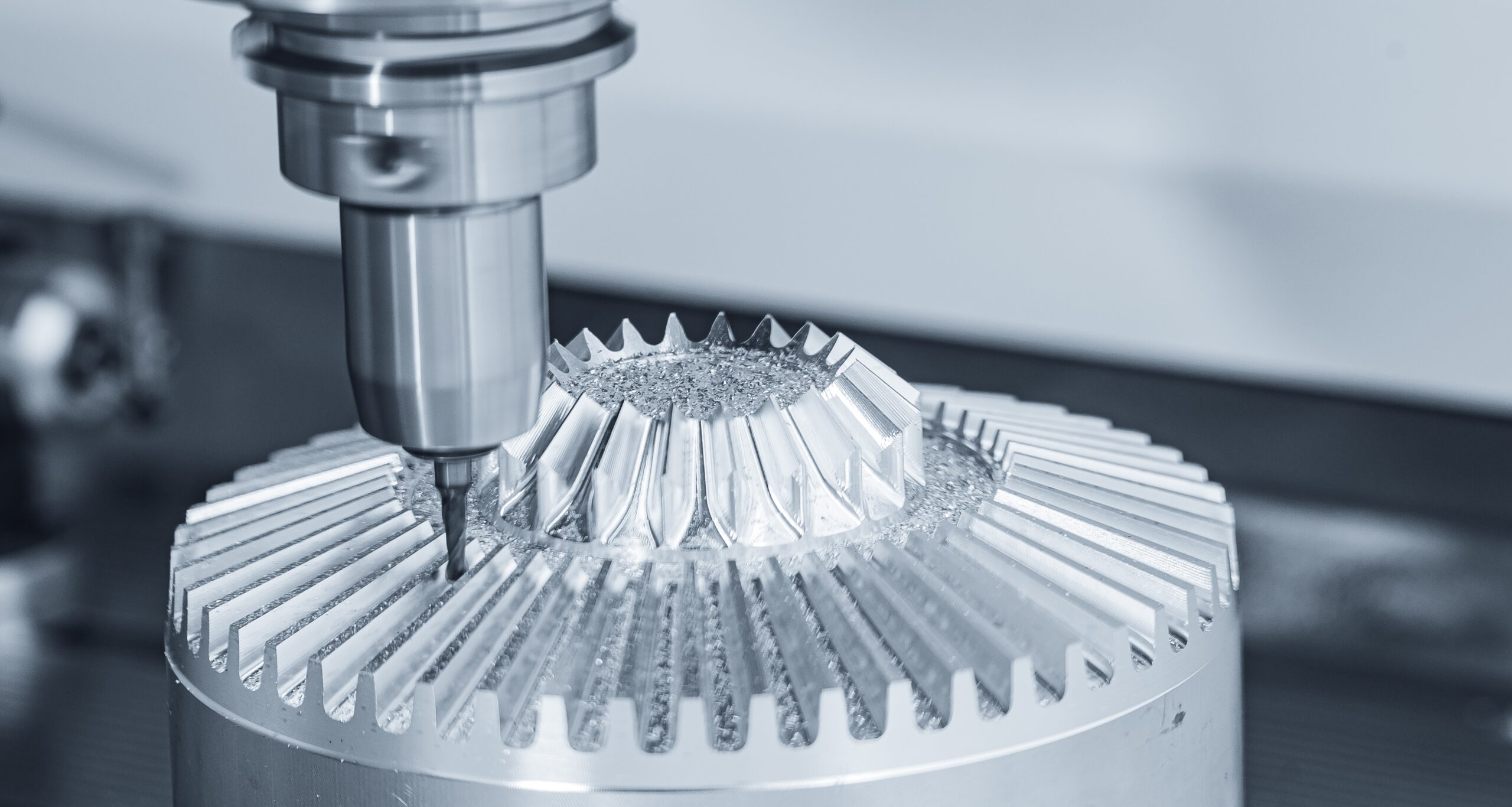

The AI-based vision system reduces inspection time and improves accuracy compared to manual inspection and traditional methods, helping manufacturers consistently meet high-quality standards. SolVision integrates seamlessly with industrial cameras and supports built-in PLC communication via TCP/IP and Modbus protocols at no extra cost.

Designed for manufacturing, food & beverage, textiles, electronics, and more, SolVision’s advanced AI vision features provide versatile and reliable AI-powered automated inspection capabilities across diverse industrial environments.

SolVision Features

Rapid Learning AI

SolVision can train an AI model in minutes using Solomon’s rapid AI model training technology, enabling fast deployment and adaptation to new inspection tasks.

Versatile AI Applications

SolVision supports a wide range of AI inspection applications, providing flexible automation solutions tailored to different industries and production environments.

Few Images Needed

SolVision can learn new items from just 1–5 sample images, reducing annotation time and accelerating AI model training and system setup.

Intuitive User Interface

SolVision’s intuitive interface allows users to label multiple defect types simultaneously, simplifying workflows even with complex objects.

SolVision Applications

Defect Detection

SolVision uses real-time AI inspection to detect defects at high speed and with high precision, improving inspection efficiency and ensuring products meet quality standards. It leverages rapid AI model training, 3D vision integration, and advanced anomaly detection to identify defects across a wide range of products and industrial applications.

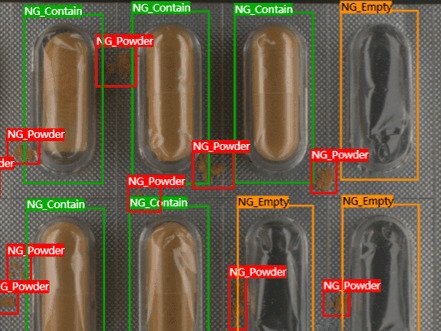

Quality Inspection

SolVision enhances industrial quality inspection by identifying defects and imperfections in real time, helping manufacturers maintain compliance with industry standards. Integrated with industrial cameras, PLC communication, and deep learning models, it delivers accurate and consistent evaluation of product quality across diverse production lines.

Classification

SolVision applies advanced deep learning to recognize and categorize items accurately from just a few sample images. Multi-defect labeling tools and minimal setup requirements streamline classification workflows, enabling precise categorization across different product types in high-throughput industrial environments.

Presence/Absence

SolVision automates visual inspection to detect missing components or assembly errors on high-capacity production lines. Using rapid AI model training, real-time 3D vision, and deep learning, it ensures accurate and efficient anomaly detection across various industrial applications.

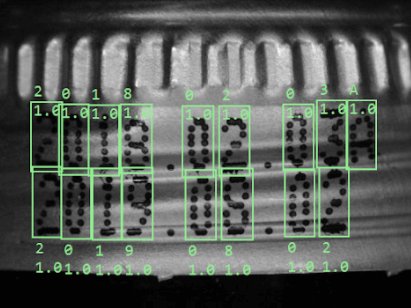

OCR (Optical Character Recognition)

SolVision’s OCR capabilities extract numbers, characters, and text from images with high accuracy, supporting automated digitization of product information. Integrated with industrial cameras and PLCs, it enables reliable workflows for shipping, labeling, compliance verification, and other operational processes.