SolVisionCase Study

Surgical Mask Inspection Using AI

Customer

The customer is a medical supplies manufacturer based in Asia.

Case

Ensuring Quality in Automated Mask Production

Medical-grade masks play a crucial role in protecting against bacteria, bodily fluids, airborne particles, and viruses. Their production is largely automated, with processes such as material cutting, ear band welding, and packaging handled by machines. Despite this automation, quality inspection remains a labor-intensive task, requiring manual effort to ensure each mask meets the necessary standards.

Challenge

Identifying Mask Defects with Traditional Inspection Methods

Mask defects can vary widely, including missing wires or components, incorrect stitching, ripped holes, stains, edge protrusions, and damaged layers. Additionally, masks are often unsystematically distributed along the production line, further complicating the inspection process. Due to these variations and inconsistencies, traditional inspection methods struggle to identify all potential defects effectively and efficiently.

Solution

AI-Powered Defect Detection

SolVision addresses the challenge of numerous defect variations by implementing an image-based inspection system. This system involves labeling mask defects on sample images, which are then used to train an AI model. Once the model is trained, which takes just a few moments in SolVision, AI accurately recognizes various defects in captured images, enabling instant identification of faulty masks on the production line.

Surgical Mask Defect Detection

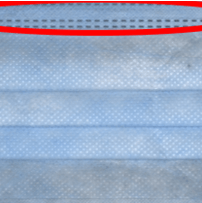

Protrusion

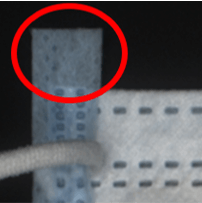

Missing Nose Clip

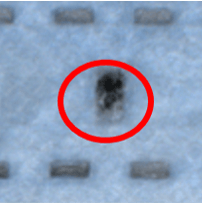

Hole

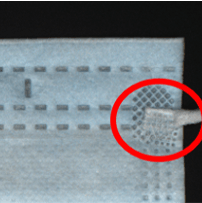

Loose Strap

Dropped Strap