SolVisionCase Study

Car Paint Defect Detection Using AI

Customer

The customer is a leading car manufacturer.

Case

Car Baking for Durable Automotive Finishes

Car baking is an advanced technique used to protect and stylize automotive body panels. Spray guns apply pigment and solvent evenly, followed by high-temperature baking, rapidly curing the paint to create a durable finish.

Challenge

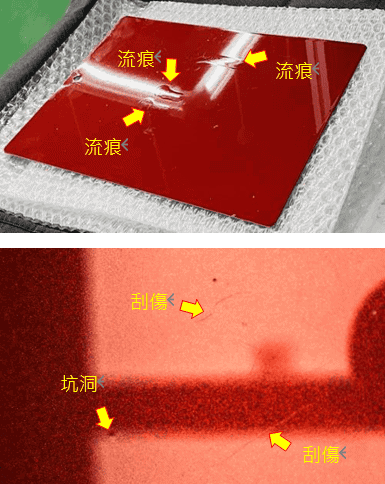

Addressing Paint Defect Inspection Efficiency

The car baking process is well-established, yet manufacturing errors like incorrect pressure or spray gun distance often cause uneven coating thickness. Issues with temperature and baking duration, mechanical impacts leading to scratches, and subpar material quality contribute to paint defects. These include surface scratches, dents, and uneven application (runs) on steel plates. Manual inspection is prone to inefficiency due to human factors like fatigue and distraction, leading to potential oversight of defects. Hence, there’s a demand for an automated inspection system to ensure both high detection accuracy and operational efficiency.

Solution

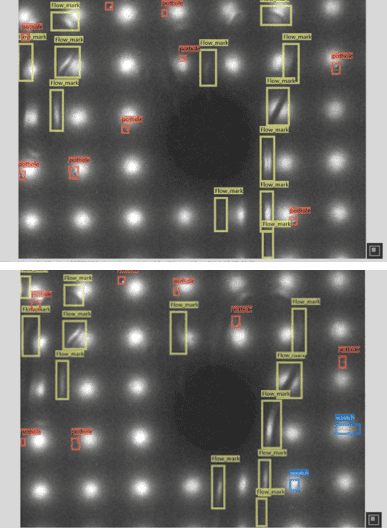

Precise Defect Detection with SolVision

Solomon’s AI vision system, SolVision, elevates industrial automation with AI-powered machine vision. SolVision utilizes deep learning to rapidly train models from a small set of sample images captured by an industrial 3D camera. This approach enables quick and precise identification and localization of defects, ensuring consistent inspection standards and efficient detection of car paint irregularities.

Paintwork Defect Detection

Car paint defects

Car paint defects detected by AI