SolVisionCase Study

AI Defect Detection for Spiral-Surfaced Metals

Inspecting Small Metal Parts with Precision

The Case: Automating Traditional Metal Processing

The metal processing industry faces multiple challenges, including harsh working environments, rising labor costs, workforce shortages, and the gradual loss of skilled craftsmanship. Compounded by global trade disruptions, manufacturers are under increasing pressure to adopt advanced technologies to maintain market relevance and deliver higher-value production.

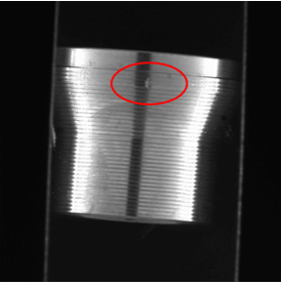

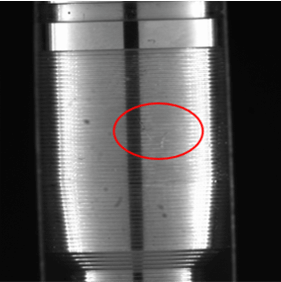

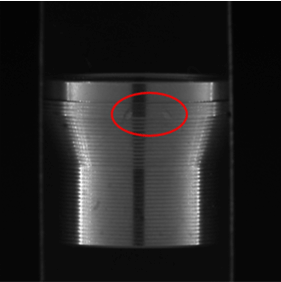

The Challenge: Inspecting Small, Spiral-Surfaced Metal Parts

Metal parts with spiral surfaces are particularly vulnerable during production. They can sustain scratches, collision damage, or cutting tool marks during handling and further processing. Their cylindrical shapes make them prone to rolling and difficult to position, especially when the components are small. Even with optimal lighting and traditional inspection equipment, manual detection of these defects is highly challenging. Missed flaws or misjudgments can result in lower quality, increased waste, and costly rework.

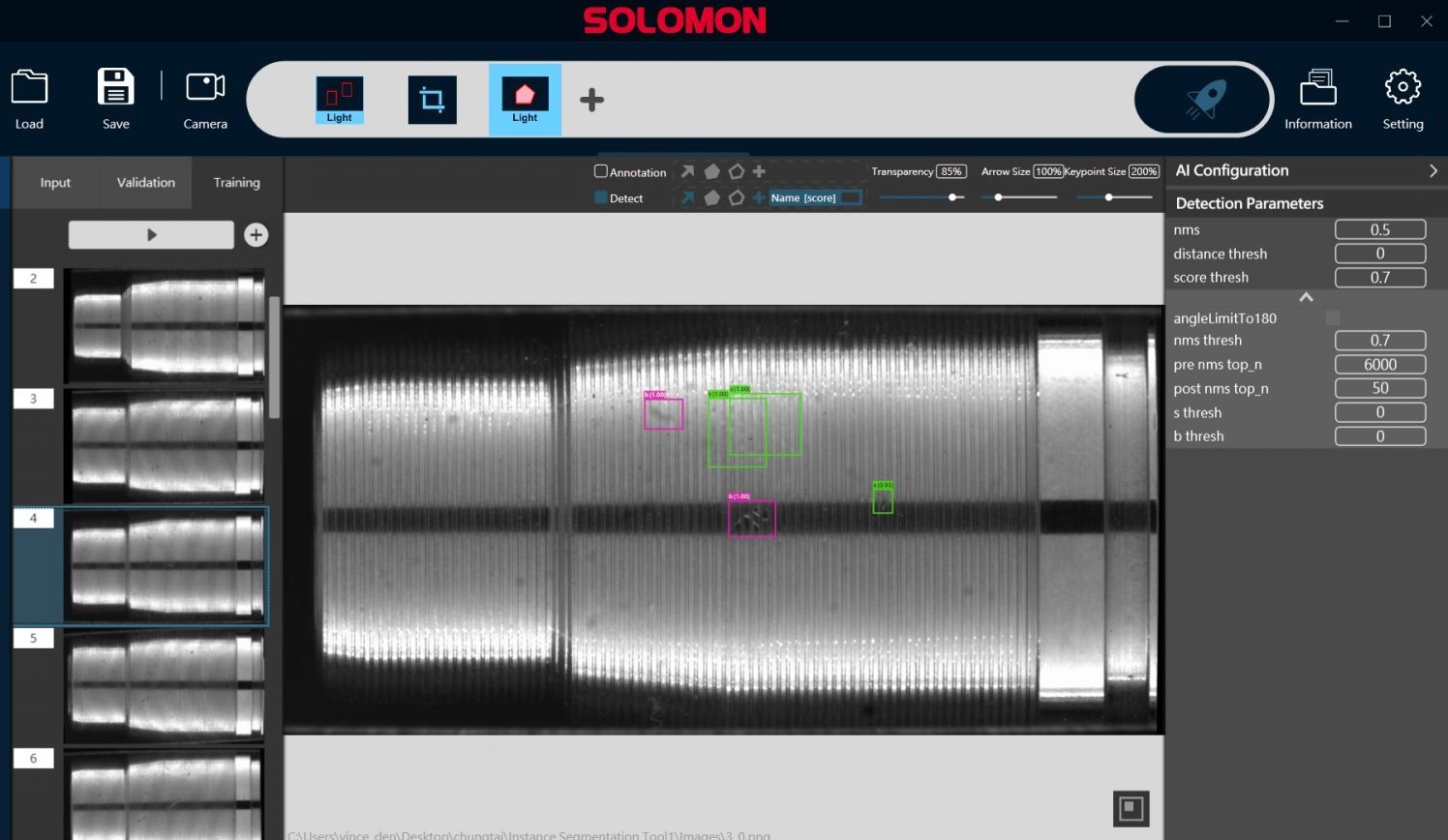

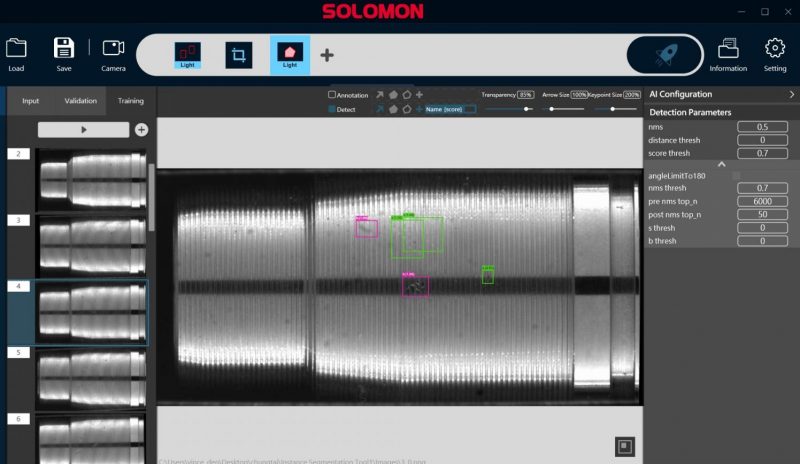

The Solution: AI-Powered Defect Detection

SolVision, Solomon’s AI vision system, provides an advanced solution for inspecting spiral-surfaced metals. Using SolVision’s segmentation tool, manufacturers can train an AI model on sample images of parts, enabling it to identify subtle cut marks, collision faults, and other surface imperfections with high accuracy. By automating defect detection, SolVision ensures early identification of flaws, reducing manual inspection errors and improving overall production quality. This AI-powered approach also accelerates throughput, enabling consistent, reliable quality control even for small or difficult-to-handle metal parts.

AI Inspection

Obscure Flaws

Tiny Surface Defects

Blemishes