SolVisionCase Study

AI Defect Detection for Spiral-Surfaced Metals

Inspecting Small Metal Parts

Automating traditional metal processing

The metal processing industry currently faces many pressing concerns, from harsh working environments and increasing labor costs, to lack of available labor and disappearing craftsmanship. Affected by ongoing trade disputes and the COVID-19 pandemic, the industry is in need of a shift to higher value production and improved technical knowhow to protect their market relevance.

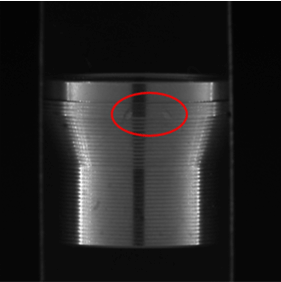

Small metal parts are difficult to inspect

Metal parts with spiral surfaces are easily injured by collisions during transfers or knife marks of turning tools when undergoing further processing. Because of their cylindrical shape, they move around easily and are tricky to manipulate especially if they are small in size. Even in ideal lighting conditions and with the right equipment, manual detection is difficult and prone to missed inspections or misjudgment.

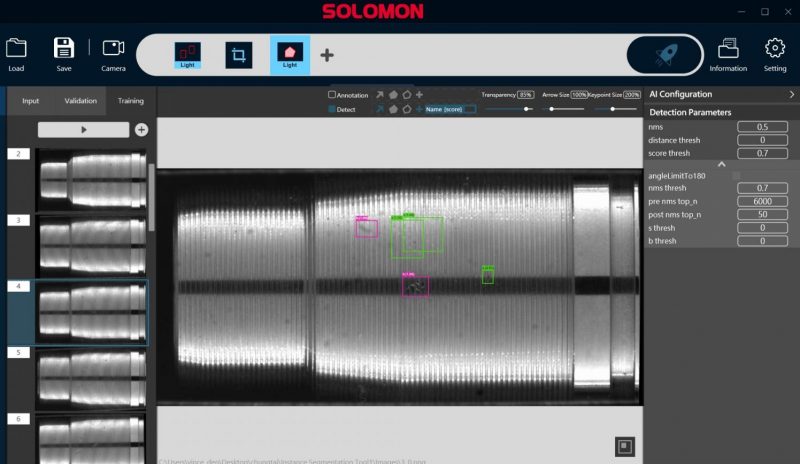

AI powered defect recognition

Small, spiral-surfaced metal parts can be inspected using SolVision’s Segmentation tool to learn the different types of cut marks or collision faults from sample images, then building an AI model to recognize these subtle defects. By identifying these imperfections in time, overall production quality can be refined.

AI Inspection

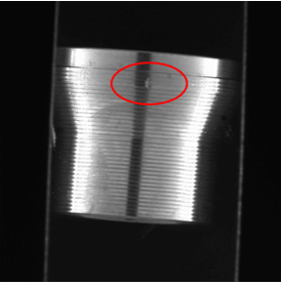

Obscure Flaws

Tiny flaws

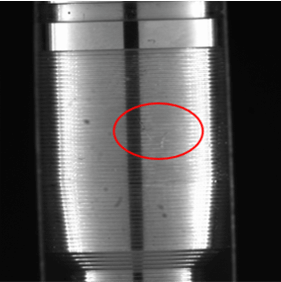

Blemishes in the shadows