SolVisionCase Study

AI Inspection for Semiconductor Components

Classifying micro transistors with Optical Character Recognition (OCR)

Monitoring production process

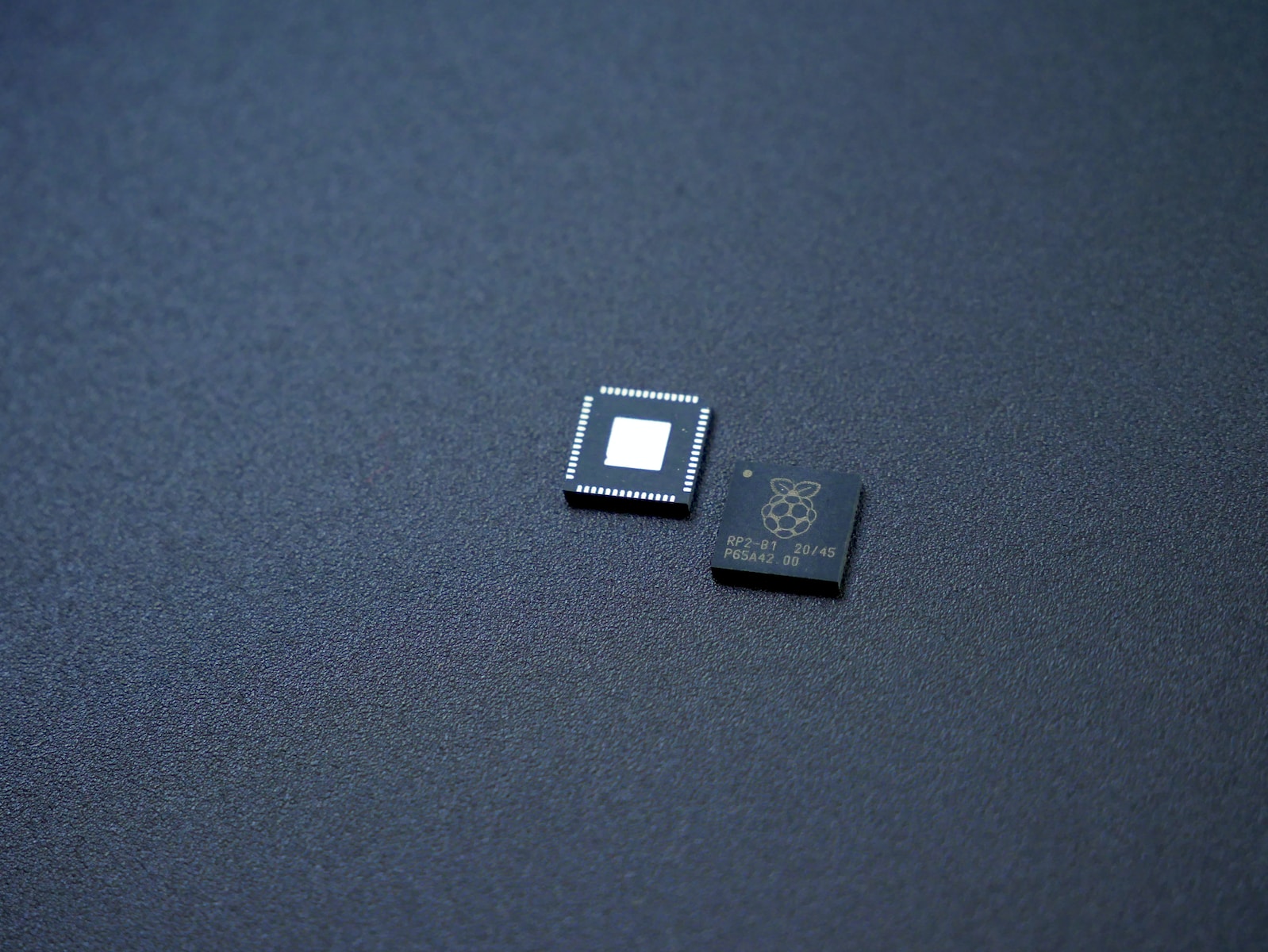

The production of semiconductors involves an extensive number of complex steps and sophisticated technology. To fully monitor the entire process, record their specifications, and quickly find defects during screening, identifying serial numbers of components such as micro transistors is a key task.

Limitations of traditional vision systems

The large volume of components and their different sources mean serial numbers also tend to vary in font type, color and size. These are difficult for rule-based inspection systems to detect, especially in poor lighting conditions and when background colors are similar. Such limitations significantly affect the accuracy of visual inspection processes, leaving room for improving production efficiency.

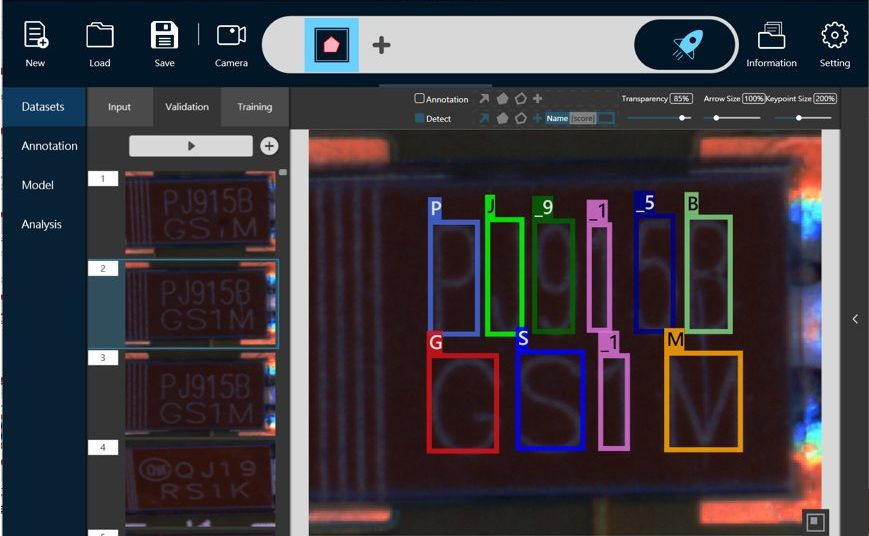

Reliable OCR using SolVision

SolVision can quickly perform Optical Character Recognition (OCR) without being affected by background or lighting conditions, complexity or appearance of the serial number. Using AI deep learning, SolVision can efficiently identify individual numbers and as the amount of sample data increases over time, the system becomes better and faster at recognition.

AI Inspection

Different fonts

Original

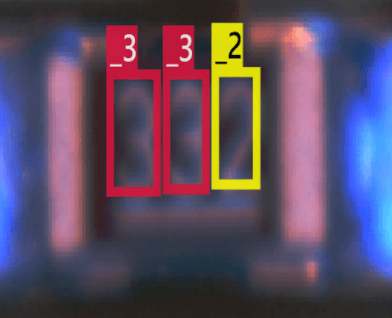

Result

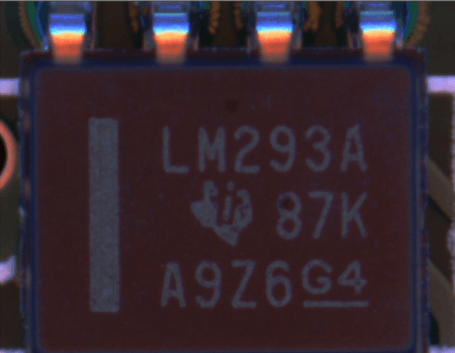

Blurred Fonts

Original

Result