SolVisionCase Study

Egg Quality Inspection Using AI

Case

Automated Cracked Eggshell Detection

Chicken eggs are widely consumed for their nutritional value, but cracked eggs pose a risk of salmonella contamination, even after thorough cooking. Robust eggshells act as a protective barrier, allowing the passage of essential gases and moisture. To ensure safety and quality, it is imperative to inspect eggshells for defects and grade them before distribution. Implementing automated AI-based systems can streamline this process, enhancing efficiency and minimizing the risk of compromised egg quality.

Challenge

Challenges in Predicting Eggshell Defects

Typically, eggshell quality is assessed based on the density of pores on the shell’s surface, categorized into different levels by common grading systems. However, the random occurrence of eggshell pores and cracks poses a challenge for predicting and detecting defective products. Eggs, processed at high speeds and specific angles on production lines, complicate traditional automation efforts. Until recently, manual inspection was the primary method, albeit with low efficiency.

Solution

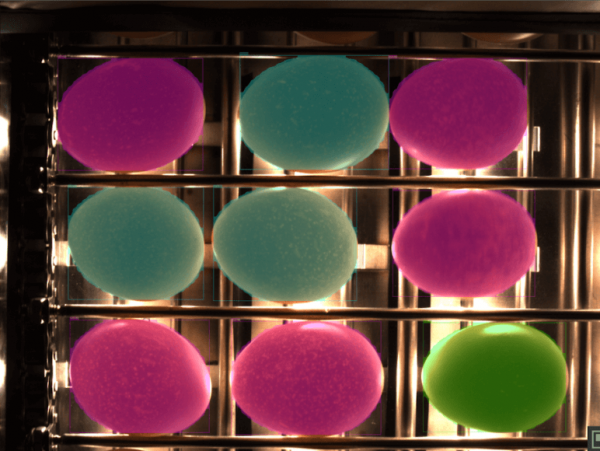

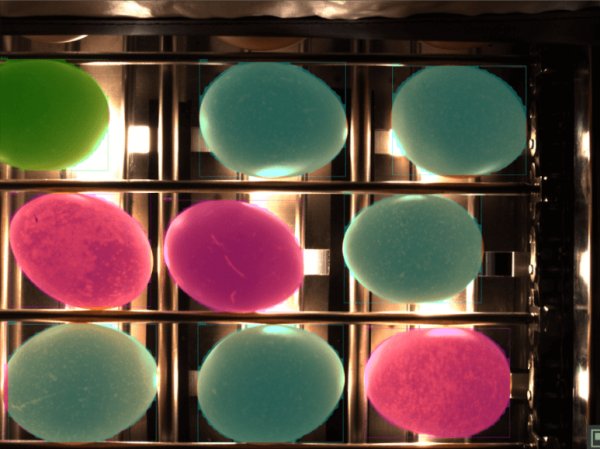

Advanced Visual Inspection with SolVision

Utilizing deep learning, SolVision employs AI technology to identify and annotate eggshell defects in sample images, training the inspection system. The AI model can detect pores and cracks on the eggshell surface, accurately categorizing eggs during the automated egg quality inspection process. This approach ensures compliance with safety standards and enhances the overall value of the commodities through improved quality control.

Egg Quality Classification

Level 1

Green

Level 2

Blue

Level 3

Pink