SolVisionCase Study

Bobbin Yarn Defect Detection Using AI

Customer

The customer is a leading textile manufacturer.

Case

Bobbin Quality in Textile Production

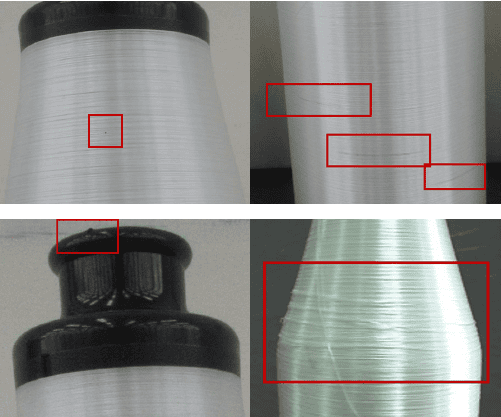

In the textile industry, bobbins are essential for winding and storing yarn, ensuring proper tension for smooth movement into looms or machines. This reduces knots and tangles, boosting efficiency and minimizing downtime. Spinning machines typically control tension and speed for even winding, but issues like yarn breakage, uneven winding, and environmental factors can cause defects such as dirt contamination, uneven layers, and yarn slippage, affecting product quality and yield.

Challenge

Limitations of AOI and Manual Inspection

With a daily production capacity of 16,000 to 20,000 yarns, the customer relies heavily on manual inspection to identify and remove defects. However, manual inspection is inconsistent due to subjective standards and is time-consuming, leading to fatigue and difficulty in detecting complex and subtle defects. This results in a high miss rate. Automated Optical Inspection (AOI) also faces challenges with irregular defects and has a high false-positive rate, requiring manual reinspection. Consequently, the customer is seeking a solution to improve inspection efficiency and streamline production line operations.

Solution

AI-Powered Solution for Enhanced Defect Detection

SolVision is an advanced industrial automation AI vision system that quickly learns, typically within minutes, to identify and locate irregular defects with high precision. It effectively handles complex backgrounds and reflections, surpassing the accuracy of traditional Automated Optical Inspection (AOI) systems. Utilizing sophisticated AI models trained with a minimal number of image samples, SolVision provides automatic visual inspection capable of detecting missing components, thereby ensuring robust quality control and efficient defect management on high-capacity production lines.

Yarn Defect Detection