HVAC Welding Quality Inspection Using AI

Case Overview

Industry: Manufacturing / Metal Processing

Solution: SolVision

The Case

HVAC Welding Quality Control

Manufacturers of HVAC and refrigeration systems rely on precise welding of components such as heat exchanger tubes, mirror plates, and front and rear headers. Welding quality is critical for system reliability, efficiency, and safety. To ensure consistent performance, these welded components require thorough inspection.

The Challenge

Detecting Complex Weld Defects

Welding environments are typically high-temperature and high-risk, making manual inspection challenging. Additionally, welding defects—such as incomplete welds, missing beads, or irregular bead shapes—can be complex and unpredictable.

Manual inspection alone often struggles to maintain consistent defect detection while keeping up with production throughput. QC engineers require a solution that ensures accuracy, speed, and repeatability.

The Solution

SolVision AI Welding Inspection

SolVision performs welding inspection on HVAC and refrigeration components, analyzing weld beads in real time. Trained on just a few sample images, the rapid AI model detects common welding defects such as incomplete welds, missing beads, and irregular shapes.

The AI vision system, powered by Solomon’s deep learning technology, provides consistent defect detection, enabling QC engineers to maintain quality standards without slowing production and reducing the risk of errors and rework.

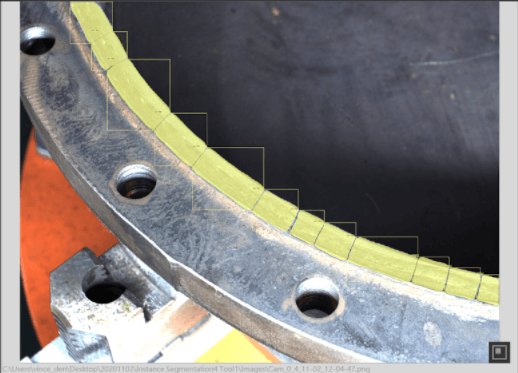

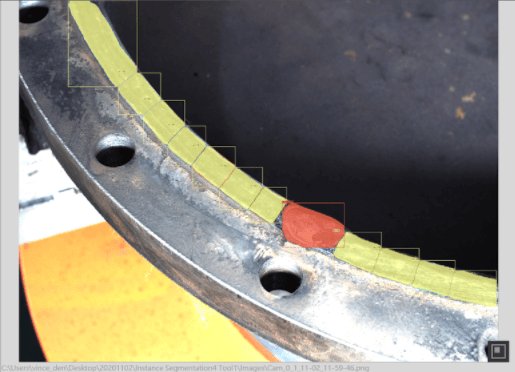

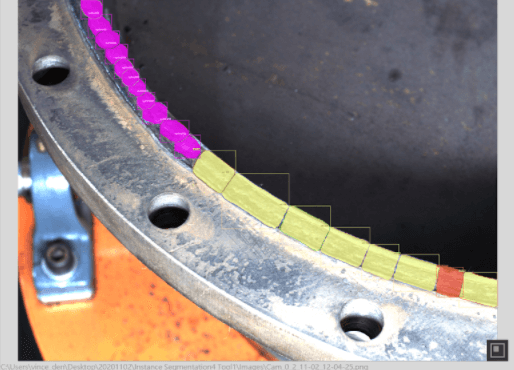

HVAC Welding Defect Detection

OK: Complete weld bead

NG: Missing weld bead

NG: Incomplete welding