SolVisionCase Study

Wrench Defect Detection Using AI

Customer

The client is a leading manufacturer of industrial-grade adjustable wrenches based in Asia, specializing in the design and production of high-quality tools for global markets.

Case

Defect Inspection in Wrench Production

Adjustable wrenches are indispensable tools in industries such as construction, automotive, and manufacturing. Their adjustable jaw design allows precise calibration to fit a wide range of bolt and nut sizes, making them essential for maintenance, installation, and repair tasks. Given their critical role, ensuring reliable, defect-free production is vital to maintaining wrench performance, durability, and reliability.

Challenge

Limitations of Automated Optical Inspection

In adjustable wrench production, defect detection is crucial for maintaining product quality. Manufacturers often rely on Automated Optical Inspection (AOI) systems with high-resolution cameras to identify visible defects such as surface scratches, cracks, and coating inconsistencies. While AOI systems are effective for detecting major flaws, they struggle with finer defects, such as minor dents, surface irregularities, or subtle finish variations, which can impact overall quality. Environmental factors like ambient lighting, background clutter, and reflective surfaces further hinder the accuracy of AOI systems, leading to missed defects or false positives. To address these challenges, the client sought a more precise, adaptive solution to improve inspection accuracy and ensure consistent quality control.

Solution

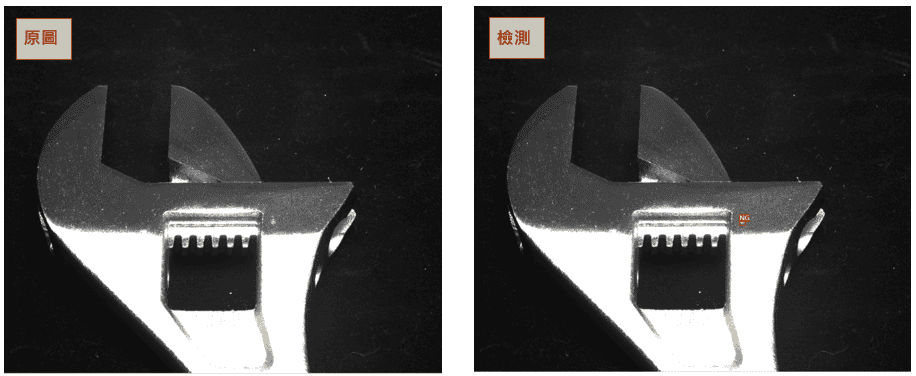

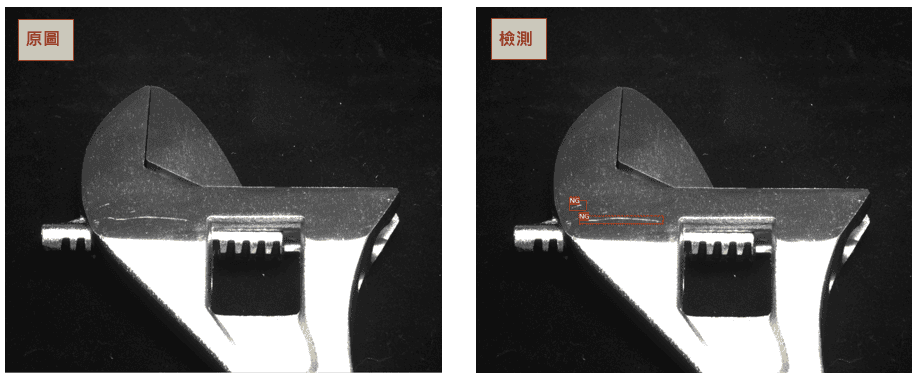

AI Defect Detection for Wrench Inspection

Solomon’s SolVision AI enhances defect detection in adjustable wrenches by addressing the limitations of traditional AOI systems. Using a small set of image samples, SolVision adapts to challenging conditions, such as complex backgrounds and reflective surfaces, that often hinder traditional inspection methods. The AI system excels at detecting surface finish defects, including scratches, cracks, and inconsistencies, ensuring a more reliable and precise quality inspection. By automating the visual inspection process, SolVision reduces false positives, improves inspection speed, and helps maintain consistent product quality. This leads to the production of durable wrenches that meet the highest manufacturing standards.

Adjustable Wrench Defect Detection