AccuPick

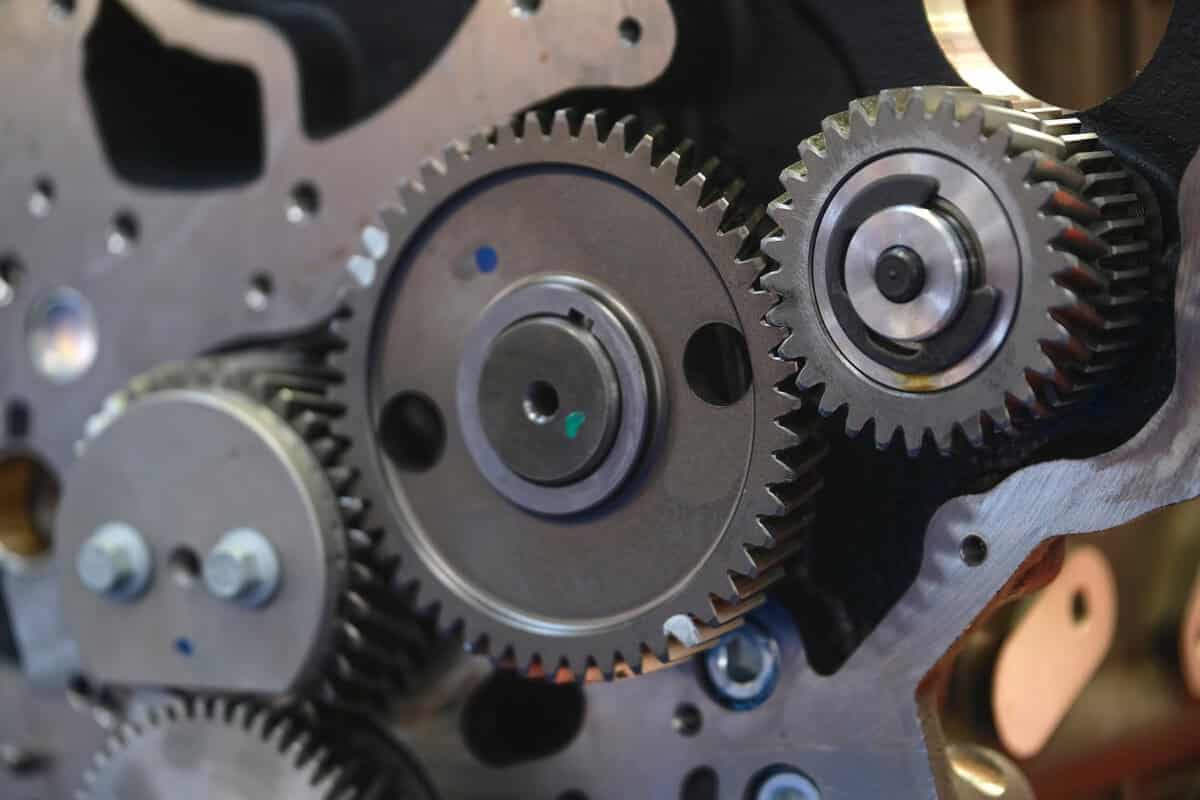

3D Bin Picking Solution

Start Picking in Minutes

Intelligent Bin Picking Features

Rapid Learning AI

AccuPick’s built-in AI learns new items in minutes from as few as 1-3 sample images through rapid AI model training.

No Coding Required

Easily build AI models without coding through AccuPick’s intuitive drag-and-drop interface.

Robot + Camera Compatibility

AccuPick works with 30+ robot brands and supports various 3D camera technologies, including Structured Light, Active Stereo Vision, Time-of-Flight, and Laser.

Seamless Integration

AccuPick integrates easily into existing systems and production lines, providing an optimal robot vision system solution.

Start Picking in Minutes

AccuPick’s drag-and-drop interface and instant training saves a huge amount of time and resources.

AccuPick 3D Vision with NVIDIA Isaac Manipulator

Solomon has integrated the latest NVIDIA technology with AccuPick, unlocking advanced motion planning, and enhancing the functionality and performance of robot arms.

Unveiled by NVIDIA CEO and founder Jensen Huang during his GTC keynote, NVIDIA Isaac Manipulator provides cutting-edge motion generation and AI capabilities.

Smart Bin Picking Applications

Pick and Place

AccuPick excels at picking complex objects, including small, transparent, reflective, deformable, and irregular items. AccuPick’s rapid AI and compatibility with 30+ robot brands helps users optimize autonomous pick-and-place tasks.

Suitable for: Heavy Lifting, Stacking Items, CNC Machining

Unknown Picking

AccuPick enables robots to identify and retrieve objects from the bin without prior knowledge of the item, location, or orientation. This allows our customers to complete unknown picking tasks with greater speed, precision, and efficiency.

Suitable for: Palletizing/Depalletizing, Warehousing, Logistics

Random Bin Picking

AccuPick streamlines material handling by using random bin picking, where robots retrieve randomly arranged or assorted objects from bins, eliminating the need for manual sorting and improving overall efficiency with unrivaled accuracy.

Suitable for: Manufacturing, Automotive, Pharmaceuticals, Food & Beverage

AccuPick Case Studies

Instant Intelligence Rapid AI Model Training

New Item Recognition in Less Than 60 Seconds

Designed for quick deployment, AccuPick is capable of recognizing items from as few as 1-3 images, completing the AI model training process in a matter of minutes rather than hours.

Add a New Item to an Existing Project

AccuPick’s advanced AI requires minimal annotations of the new object, avoiding the need to retrain the AI model with existing items, ensuring maximum efficiency and minimal downtime when adding new items to a bin picking task.

Select Pick-Point and Orientation

AccuPick quickly determines precise picking points and orientation, eliminating the need for extensive annotations and prolonged model training associated with traditional AI-based bin picking systems.