硬盘支架检测影响电脑组装良率

电脑组装良率关键:硬盘支架检测

在电脑的整个生产过程中,硬盘支架的良率是整个制程过程中要求的项目之一,其良率会影响到传播及动力等关键的性能。

制程优化困境:瑕疵种类繁多且细微

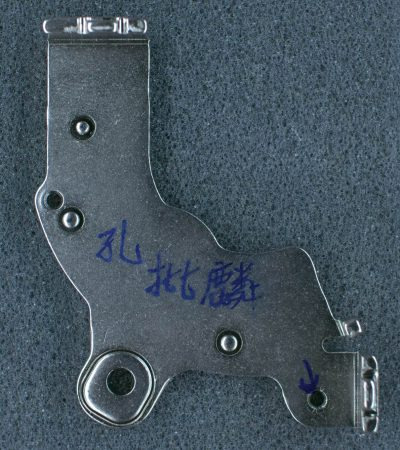

硬盘支架制造过程出现的瑕疵种类繁多,包括金属的压伤、表面白雾、孔批麟、孔黑等等,透过人工检测不容易逐一检出,然而微小的缺陷在组装过程可能造成孔隙无法对齐等问题发生。

完善制程新亮点:瑕疵检测

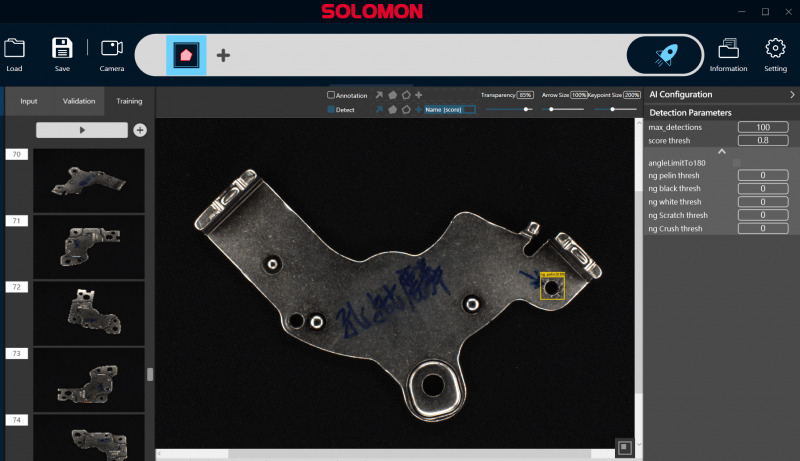

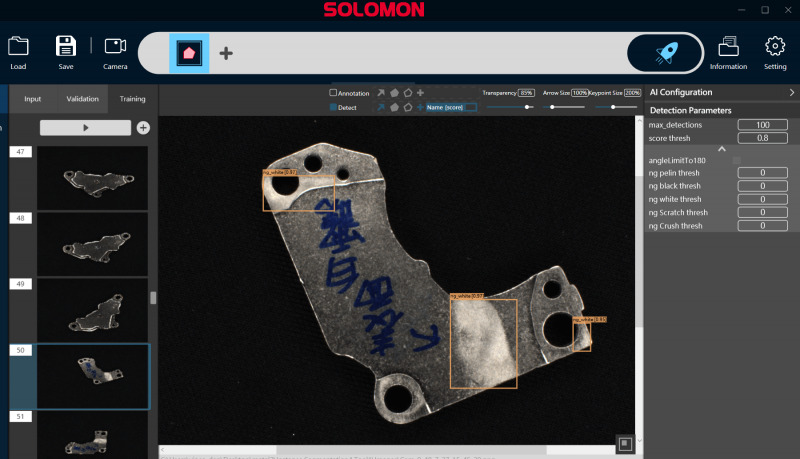

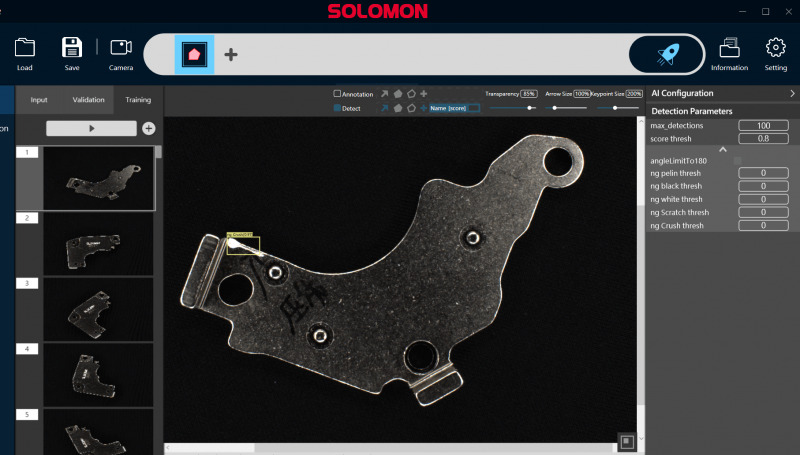

使用 SolVision 的实例切割技术,针对金属支架上瑕疵的形状来训练AI模型,AI学习瑕疵特征后,能够快速检测出硬盘金属支架上的各类微小瑕疵。

金属瑕疵检测案例

表面白雾

压伤

孔洞瑕疵