SolVision成功案例

袜品外观缺陷检测

纺织物外观瑕疵检出并分类

织品瑕疵人工检测困境

袜品生产流程可分为:设计、织袜、车缝、翻袜、定型,最后是品检包装。纺织产业属于劳力密集产业,品检关卡原由人工目视检测,然而人工检测不仅检出率低、也容易因视觉疲劳造成袜品外观缺陷检测速度缓慢。

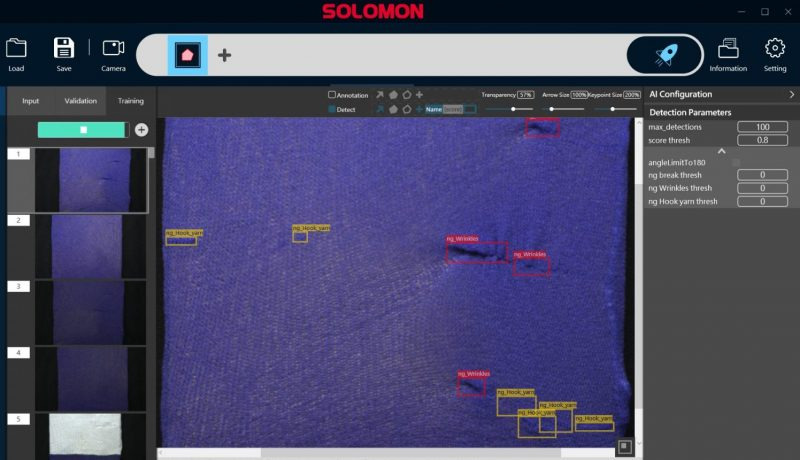

袜品瑕疵多样,自动光学检查(AOI)仍需人工复检

袜品瑕疵形态多样,包括:勾纱、皱褶、勾破等,且形状大小与出现位置皆不固定,传统 AOI 适合用于整块布匹的检测,对于不固定的瑕疵检测有困难,且容易发生错杀,仍需人工进行复检。

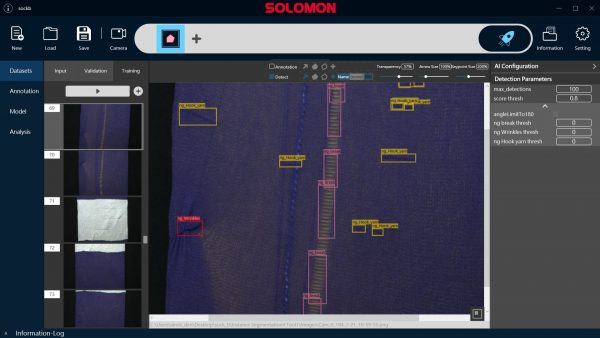

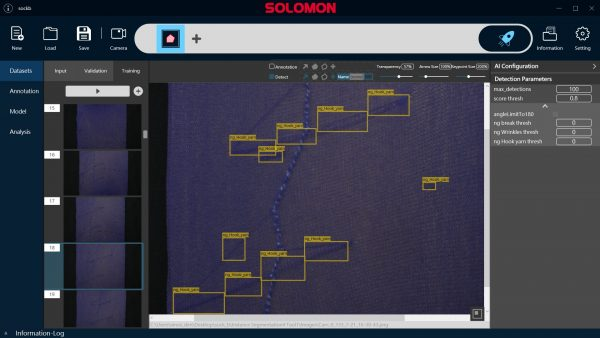

AI可以快速精准检测瑕疵,提升生产效率

搜集袜子勾纱、皱褶等瑕疵的影像,以 SolVision 的实例切割技术完成AI模型的训练。可快速且精确地找出瑕疵、分类不同瑕疵并剔除不良品,把关产品品质、提升生产效率,透过对瑕疵进行分类与分析,更能够优化整体制程。

瑕疵分类范例

勾纱1

皱褶

勾纱2

勾破