SolVisionCase Study

Processed Food Inspection Using AI

Case

Safeguarding Hygiene and Quality in Food Processing

Maintaining hygiene and safety standards is paramount in processed food production. Stringent quality assurance procedures are imperative to uphold these standards, making visual inspection during the production stage indispensable for ensuring consistency and quality.

Challenge

Efficiency and Quality Assurance with Manual Food Inspection

In food production, the appearance of processed food can vary, and products are often randomly distributed on the conveyor belt. Traditional manual food inspection, despite employing large manpower, has never achieved full efficiency. Moreover, excessive manpower on the production line can lead to sanitation concerns. Food brands aiming to optimize throughput seek smarter solutions capable of monitoring product quality and detecting anomalies.

Solution

SolVision Smart Solution for Food Inspection

Solomon’s machine vision inspection solution, SolVision, harnesses AI to learn diverse defect types and swiftly recognizes them as products move through fast-paced conveyor systems. Real-time AI imaging and analysis replace manual inspection, enabling the identification of defective products without the need for extensive AI model training.

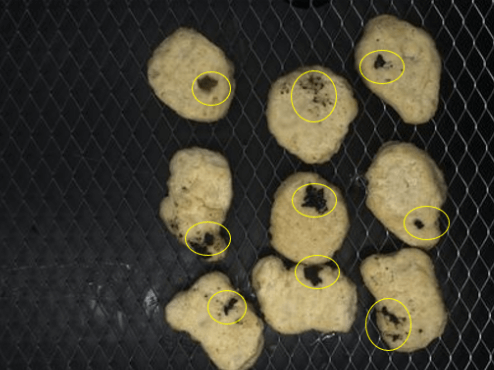

Chicken Nugget Defect Detection

Overcooked

Conjoined

Burnt

Greasy