SolVisionCase Study

Cable Insulation Defect Detection Using AI

Customer

The client is a multinational manufacturer specializing in wires, cables, and associated components for the electronics and telecommunications sectors.

Case

Cable Sheath Inspection

The cable sheath protects internal conductors from moisture, chemicals, and physical damage. Maintaining cable insulation integrity is critical, as defects such as cracks, abrasions, or inconsistent thickness can compromise performance and safety, especially in electronics and telecommunications.

Challenge

Achieving Precision in Cable Inspection

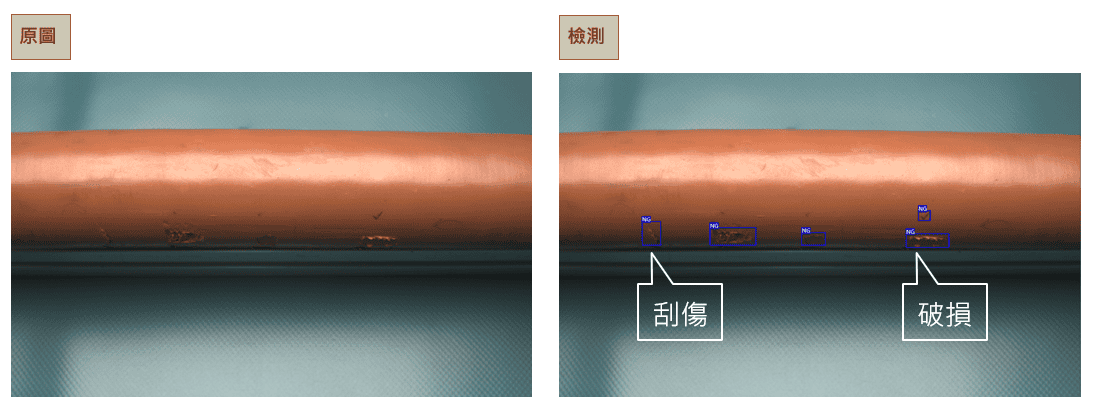

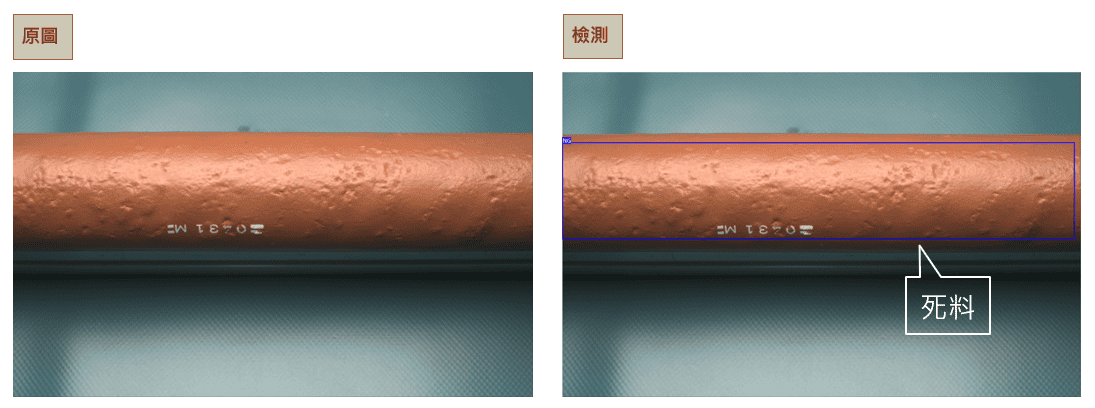

Inspecting cable rolls of 300 to 400 meters requires mechanical equipment to straighten the cables before scanning with line lasers. This method detects surface defects like breaks, indentations, and scratches, but struggles to differentiate between printed text and actual flaws. Variations in angles and lighting exacerbate misjudgments, necessitating manual rechecks, which reduce inspection efficiency. The customer needed a more accurate solution to distinguish text from genuine defects.

Solution

AI-Driven Cable Defect Detection

The customer used Solomon’s SolVision AI technology to enhance defect detection in cable manufacturing. Within SolVision, AI models were trained using only a few sample images of defects—such as stains, deformations, and scratches—enabling accurate differentiation between true defects and printed text or surface variations. This precise detection reduced false positives, minimized manual rechecks, and accelerated the inspection process. As a result, the client achieved higher inspection accuracy, improved production efficiency, and enhanced cable quality and yield.

Cable Sheath Defect Detection