SolVisionCase Study

AI Visual Inspection of Drywall Panels

Detecting subtle defects in complex backgrounds

Drywall panels in building construction

Shaped like boards, drywall is commonly material in construction known for its fire and earthquake resistance, heat and sound insulation properties. It is used for building ceilings and walls, and in recent years have been offered in different embossed patterns and prints that break away from stereotypical impressions.

Complex embossed patterns and craftsmanship

Before a drywall leaves the production line, it is checked for cleanliness and pattern consistency. Stains, dirt, excessive or unclear printing need to be detected. However, the unique characteristics and appearance of embossed patterns create fuzzy looking defects on complex backgrounds that manual and conventional inspection systems have trouble identifying.

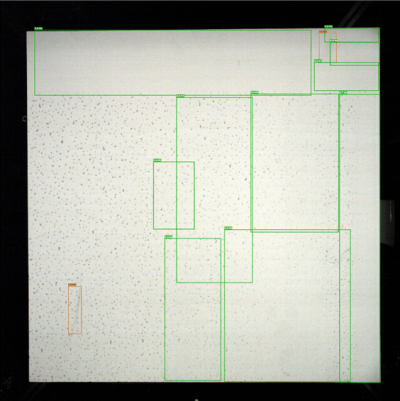

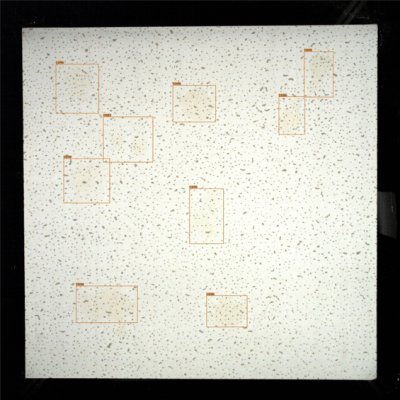

AI enabled advanced visual inspection

Powered by AI, SolVision can automate visual inspections through high level image processing, recognizing defective products regardless of defect type or severity. The AI model can be trained to accurately detect and locate the defects on the drywall to improve product quality and production yield.

AI Inspection

Incorrect Embossing and Scratches

Dirt

Overlarge Embossing Pattern