SolVisionCase Study

Woven Fabric Defect Detection Using AI

Customer

The customer is a prominent textile manufacturer that produces a diverse range of fabrics, supplying major clothing brands.

Case

Colored Textile Defect Detection

Textile production entails a series of precise steps. It begins with sorting fibers by color, followed by spinning, stretching, and twisting to create uniform yarns. These yarns undergo dyeing, printing, and weaving to produce high-quality fabrics for various applications.

Challenge

Limitations of Traditional AOI Inspection

Colored textiles, known for their diverse colors and intricate designs, present unique challenges in defect detection. Common issues such as small spots, fine lines, or subtle color variations lack distinct patterns, making them difficult to identify accurately using traditional Automated Optical Inspection (AOI) systems. These systems can struggle with variability in color and patterns, leading to false positives where normal textures are incorrectly flagged as defects or overlooking subtle anomalies. This complexity complicates quality control efforts, potentially impacting operational efficiency and product integrity.

Solution

SolVision for Enhanced Defect Detection

SolVision provides an advanced solution for defect detection in woven fabrics, surpassing traditional AOI methods. SolVision’s instance segmentation AI tool allows defects to be swiftly and accurately identified across woven fabric textures. The AI model is trained to detect minor, irregular, and complex defects, ensuring rapid and precise quality control in textile manufacturing. SolVision enhances production quality by enabling defect traceability and process efficiencies, optimizing operations in the textile industry.

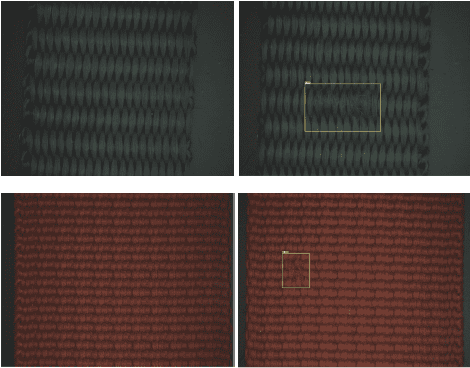

Woven Fabric Defect Detection