SolVisionCase Study

Automated Visual Inspection for LEDs

AI defect detection of LED PBCs and solder pads

Miniature LEDs: next generation display technology

With the widespread use of smaller LEDs in consumer electronics for better lighting performance, LED miniaturization is imminent. Mini and micro LEDs are only a fraction of the size of traditional LEDs, featuring reduced chip size and smaller components produced through more refined processes.

LED testing and defect detection

Quality control of mini LEDs are based on the inspection of pin holes and solder pads to ensure common defects such as burrs, oxide impurities, scratches are eliminated in time and do not cause production losses. These flaws tend to be small and discreet, blending into micro components and the background of captured images, making it hard for traditional visual inspection systems to efficiently detect them.

Streamlined LED visual inspection with AI

SolVision features a Segmentation tool designed to identify various mini LED defects through image processing. The software’s deep learning technology enables the trained AI model to accurately recognize and label different types of defects, while the Detect Region tool can be used to specify areas that need to be inspected, or mask areas that do not have defects and do not need to be inspected, to speed up the detection process.

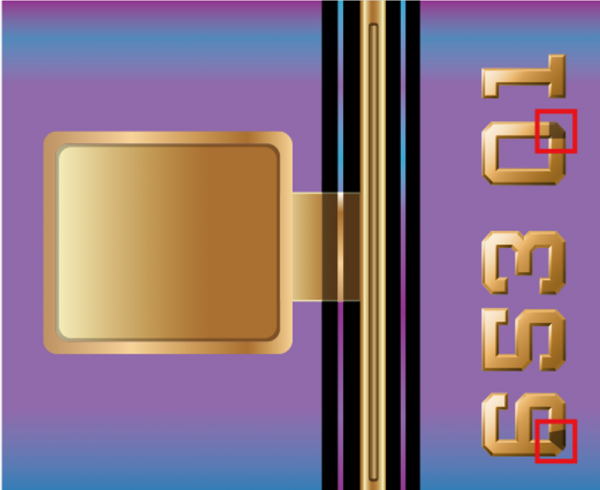

AI Inspection

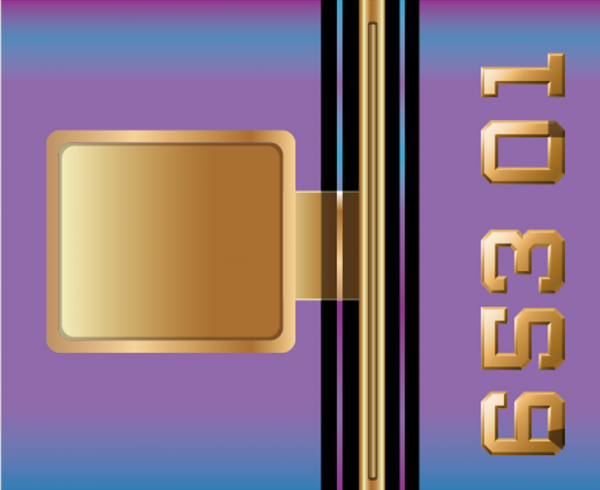

Scanned Image

Inspection Result