SolVisionCase Study

Plastic Buckle Clip Inspection Using AI

Case

Quality Control in Plastic Buckle Clip Production

Plastic buckle clips, essential components in the fashion, apparel, and textiles industries, are typically produced through injection molding. This process, which manufactures large quantities of plastic buckles, can be affected by several factors such as raw materials, mold quality, temperature, and pressure. These variables often lead to defects in the buckle clips, making precise inspection and defect detection using AI crucial to ensure quality and consistency.

Challenge

Identifying Defects in Plastic Buckles

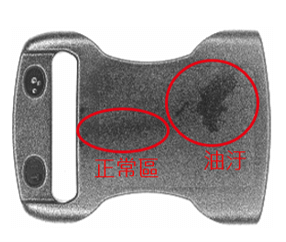

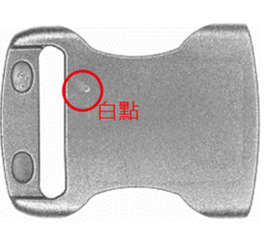

During the production of plastic buckle clips, various surface defects can arise, including oil stains, white spots, burrs, and debris. These defects can significantly affect the quality of the buckles. Among these issues, oil stains are especially challenging to detect, as they are often subtle and difficult to identify using traditional inspection methods or rule-based systems. This makes effective defect detection crucial for ensuring the integrity of plastic buckles.

Solution

AI-Based Defect Detection

SolVision offers an AI-driven solution for the inspection of plastic buckle clips. This machine vision system features specialized AI tools, each tailored to tackle various inspection tasks. Using advanced deep learning technology, the segmentation and classification tools work in tandem to identify multiple defects, including hard-to-detect oil stains, in real-time. This comprehensive approach ensures precise defect detection, enhancing the quality of plastic buckles and improving overall production efficiency.

Plastic Buckle Clip Defect Detection

Oil Stain

White Stain

Burrs

Burrs