SolVisionCase Study

AI Inspection of Stamped Metal Parts

Classification and positioning of metal surface defects

Stamping process of electronic and mechanical products

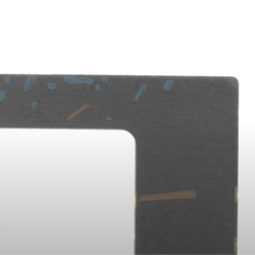

Stamping is a metal processing method that relies on pressure tools and molds to deform or separate metal pieces to required shape and size. During stamping, the surface of the metal cannot be damaged so that it remains suitable for spray painting, electroplating and other processes. However, the production environment and random factors can create minor imperfections on stamped parts such as corner burrs, dirt, water stains, indentation, and scratches that need to be detected immediately to facilitate subsequent processes.

Quality control and obscure defects

There are many types of defects that may appear differently each time on the stamped parts, in particular oil or water stains, which are not easily detected. Brightness levels during image acquisition can also vary, which makes implementing traditional inspection systems challenging.

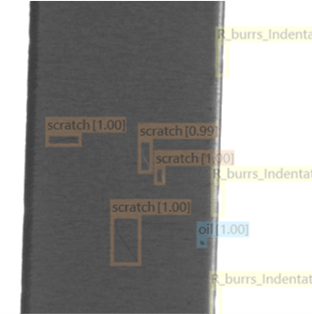

AI enabled defect detection with SolVision

Using SolVision’s segmentation tool, an AI model can be trained using images of different defects in varying brightness to develop an inspection system that can easily detect defects on stamped metal parts, and improve the surface quality before further processing.

AI Inspection

Defect classification

Blue Oil stains, water stains

Green White defects

Orange Scratches

Yellow Burrs and dents

Original

Result

Result

Result