SolVisionCase Study

Tablet Inspection Using AI

Customer

The customer is a prominent multinational pharmaceutical company.

Case

Quality Inspection of Tablets

Following production, tablets undergo thorough quality inspection to verify compliance with specifications for size, texture, shape, color, and labeling accuracy. This meticulous process includes rigorous screening for contaminants or foreign objects that could affect tablet integrity. Swift identification and removal of damaged tablets or irregularities are crucial to prevent potential recalls and uphold the company’s reputation.

Challenge

Limitations of Traditional Inspection Methods

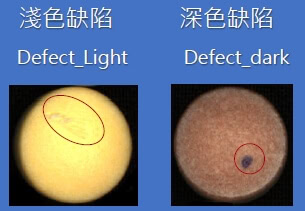

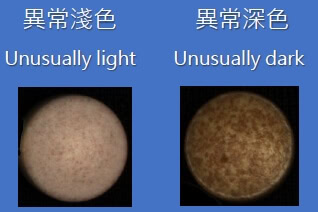

Pills and tablets may exhibit defects such as inconsistent shape and size, color fading, and external flaws, which can vary significantly. Automated Optical Inspection (AOI) machines often struggle to reliably detect these defects, necessitating frequent manual inspection. However, prolonged manual inspection can lead to fatigue and higher error rates, posing challenges to effective quality control processes.

Solution

Enhanced Inspection with SolVision

SolVision AI’s visual defect detection tools empower manufacturers to utilize image-based learning for identifying various types of defects specific to pharmaceutical tablet production. This innovative technology enables real-time defect detection and continuous learning, allowing SolVision to adapt and enhance its capabilities by incorporating newly identified defects. This capability significantly improves production efficiency and yield rates on the tablet production line.

Pill Defect Detection