SolVisionCase Study

AI Quality Control for Medical Consumables

quality-control-of-medical-equipment

Improving Medical Equipment Quality

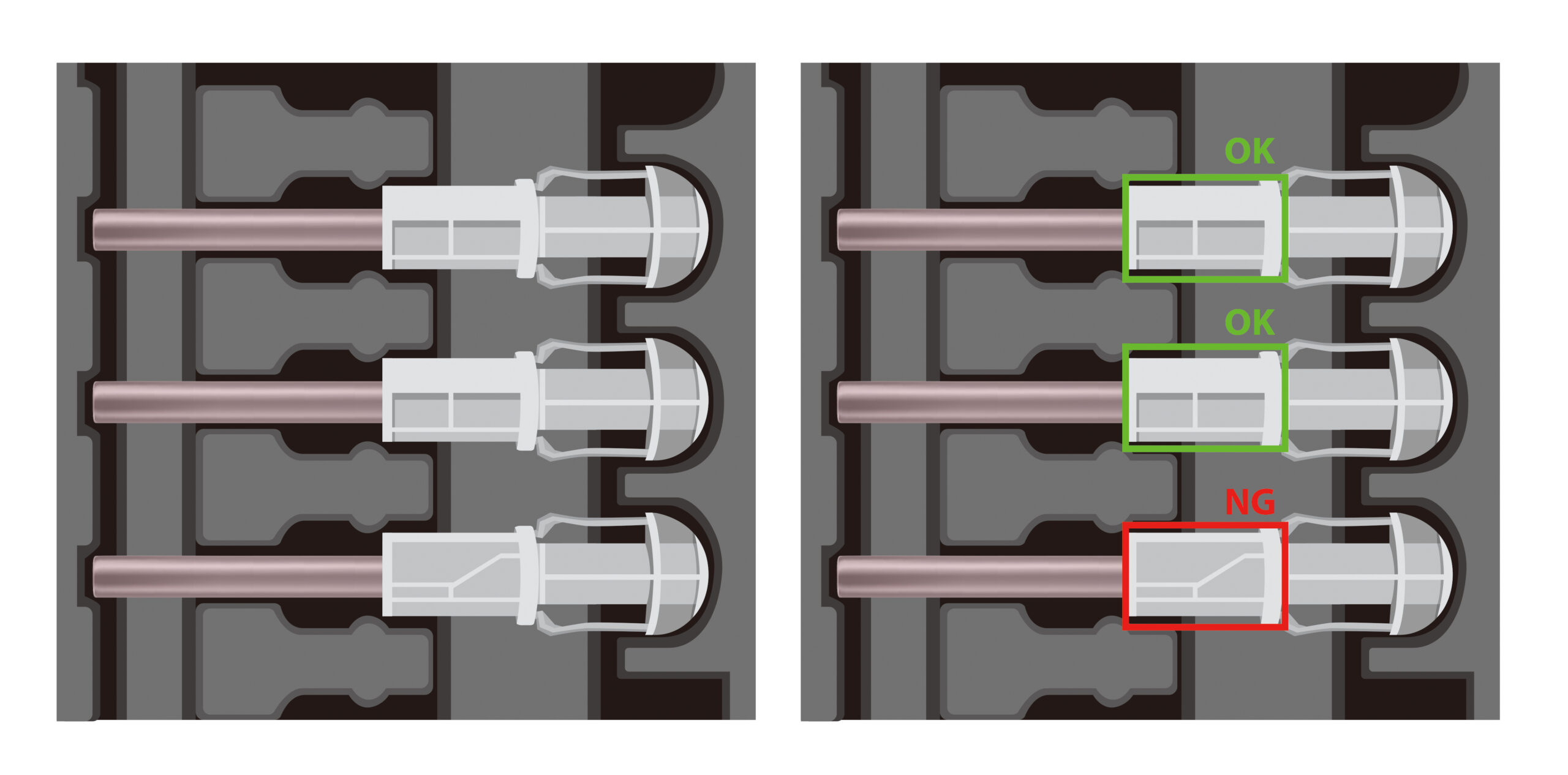

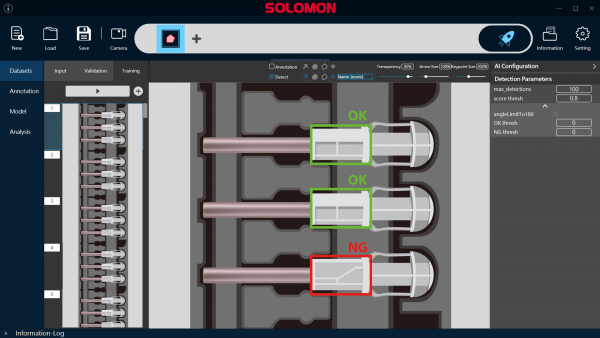

Safety syringes comprise several dozens of different components, including a built-in needle that can be detachable or permanently attached. The assembly process requires inspection checks to monitor and backtrack when production errors occur. Defect detection can be used to improve product quality and production processes.

Traditional Inspection Limitations

When needles of safety syringes are assembled incorrectly, this results in protruding or malfunctioning needles that can cause injury, and be unusable. Safety syringes are often made of materials and textures that are difficult for traditional rule-based inspection systems to inspect.

AI Defect Detection

Bridging artificial intelligence with machine vision, SolVision can be used to develop an inspection system capable of recognizing and analyzing white or transparent parts in various textures and shapes. The advanced software can accurately detect assembly errors to identify faulty autoinjectors and lapses in production processes, and optimize throughput.

AI Inspection

Inspection