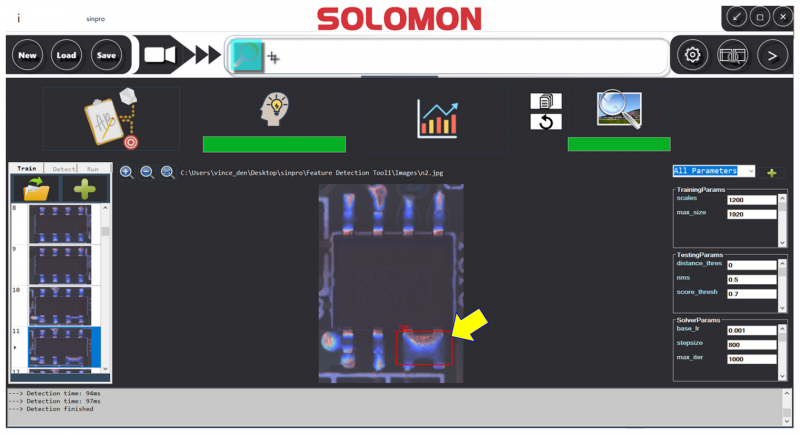

SolVisionCase Study

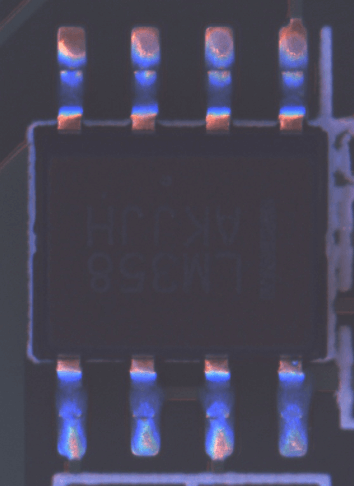

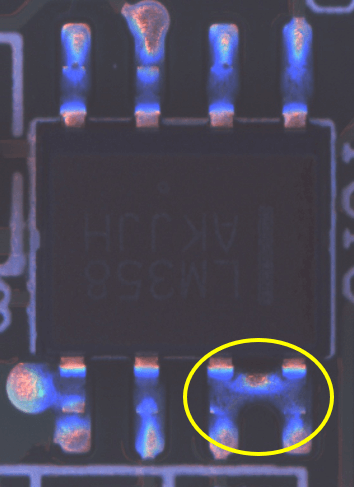

Detecting Short Circuits in SMT Soldering

AI inspection of semiconductor soldering connections

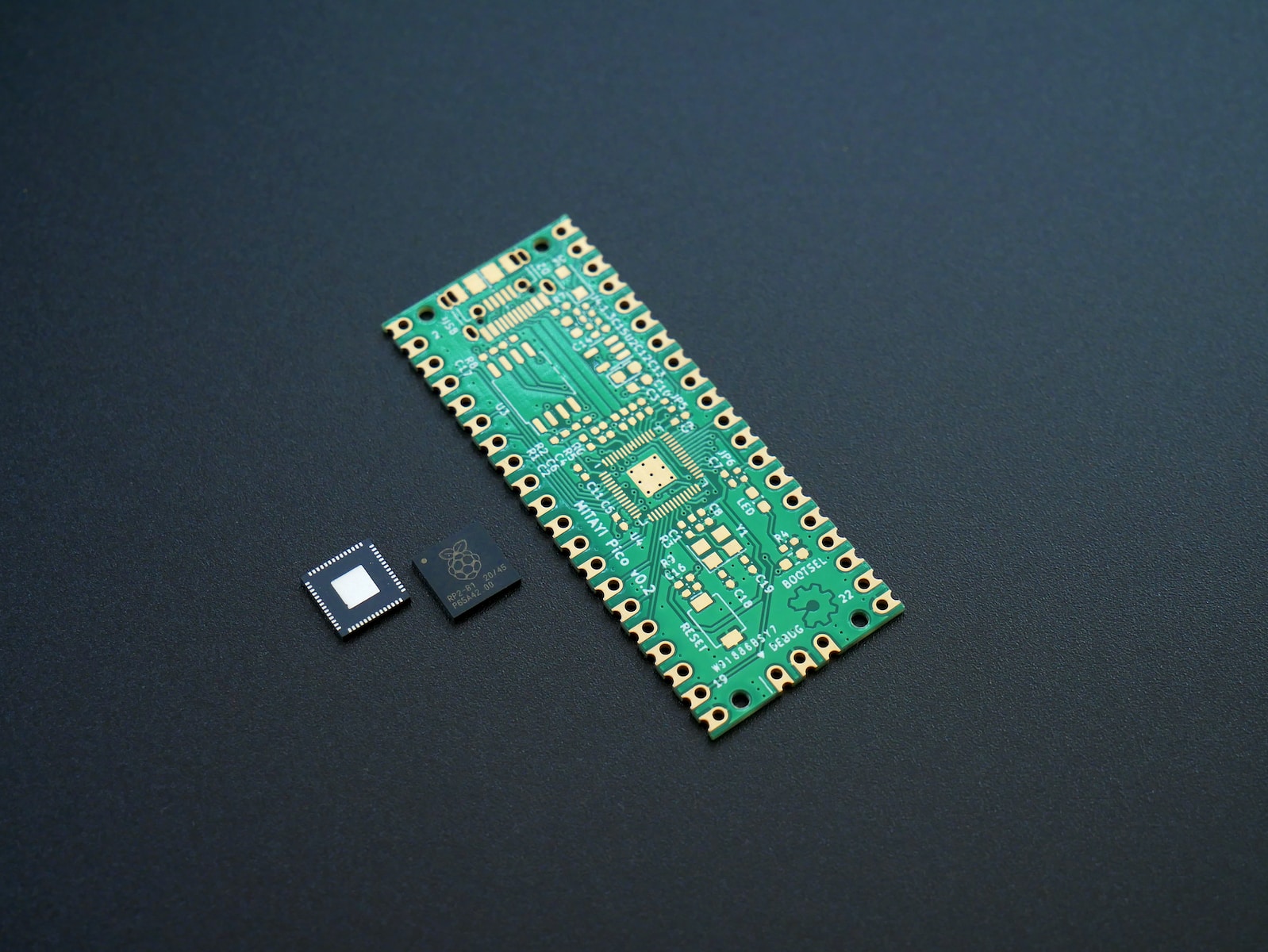

PCB reliability and the SMT process

Surface Mount Technology (SMT) is a major soldering process in the electronics industry. It involves solder paste printing, dispensing, placement, reflow soldering and other processes to connect electronic components with a PCB. During the reflow process, short circuits can occur with overflowing solder balls, and so need to be detected amongst the many components of PCBs in time to prevent complete failure of the semiconductor.

Imprinting flaws and shadows

Identification numbers are often imprinted onto the engine, so when images are captured they are susceptible to shadow interference, uneven fonts or uneven lighting. This makes it hard for machines to process the numbers, and with manual inspection, the process remains slow.

Converting images into data with AI

Using Solvison’s Segmentation tool, sample images of identification numbers can be used to train an AI model to perform Optical Character Recognition (OCR). With OCR, identification numbers can be analysed and converted into numerical data for logging into the factory’s database and connecting with the car identification number in real time.

AI Inspection

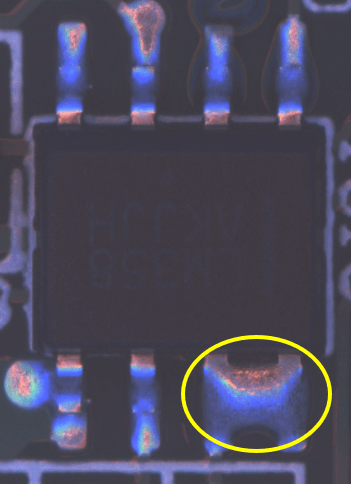

Golden Sample

Overflowing Solder Balls

Overflowing Solder Balls