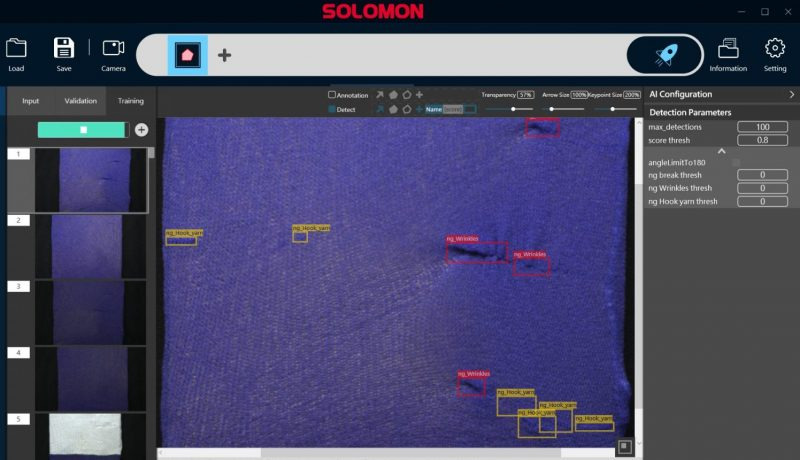

SolVisionCase Study

AI Visual Inspection of Socks

Defect detection and classification for textiles

Problems with manual inspection

The production process of socks can be broken down into: design, knitting, sewing, shaping, inspection, and packaging. Textiles is a labor intensive industry, and quality checkpoints are usually manually operated. However, manual inspection is prone to low detection rates as visual fatigue of workers is common and slows down production.

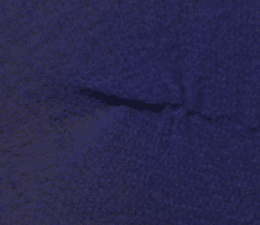

Missed detections with conventional systems

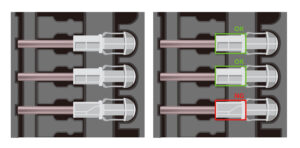

Socks are vulnerable to many different kinds of unwanted defects including sewing faults, holes or rips which can vary in size and location. Traditional rule-based vision systems are suitable for inspecting whole pieces of fabric, but do not excel in detecting irregular flaws and often require extra manually checking.

AI powered defect inspection

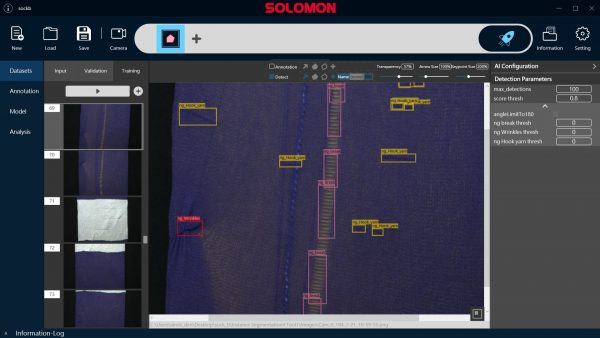

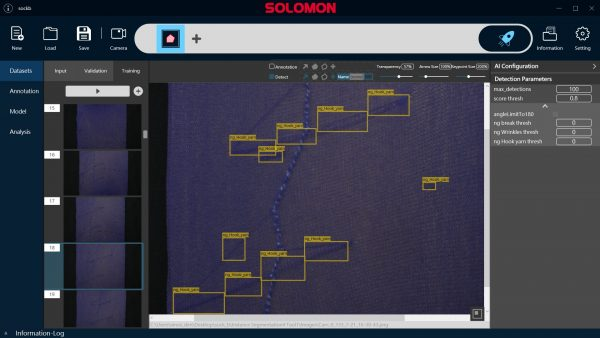

After being trained with a small set of sample images, SolVision can identify defective products in real-time. The system is capable of recognizing defects quickly and accurately, as well as classifying them to eliminate substandard products. By analyzing defects through images, SolVision can help safeguard product quality and improve production efficiency.

AI Inspection

Different fonts

Needle Mark

Seam Puckering

Needle Mark

Broken Needle