SolVision 所羅門 AI 瑕疵檢測 檢出 AOI 檢不出的瑕疵

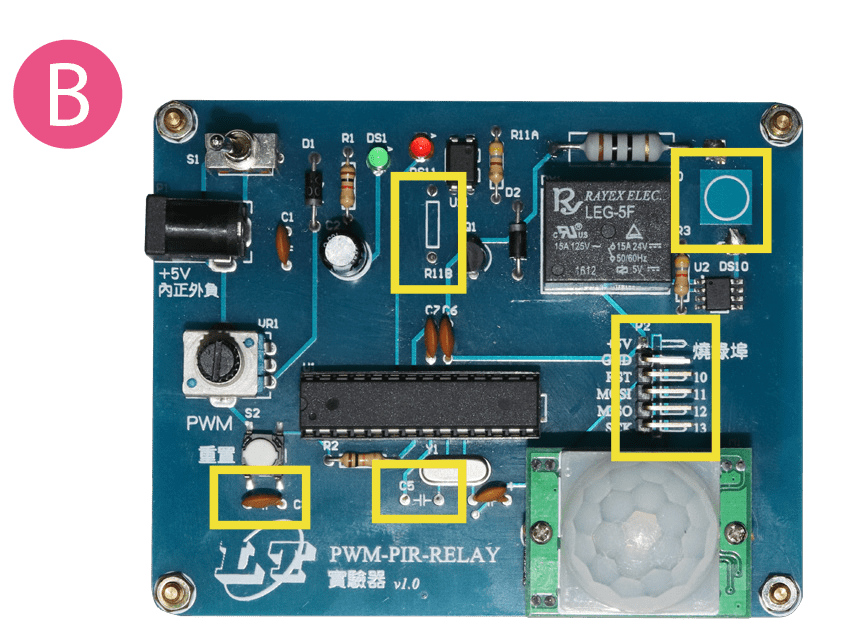

工業自動化 AI視覺系統

AI 視覺檢測優點,為何選擇所羅門?

AI 快速學習

超越 AOI 的強大辨識力

僅幾分鐘即可完成學習,輕鬆辨識並定位不規則瑕疵或特徵,解決傳統 AOI 誤判問題。

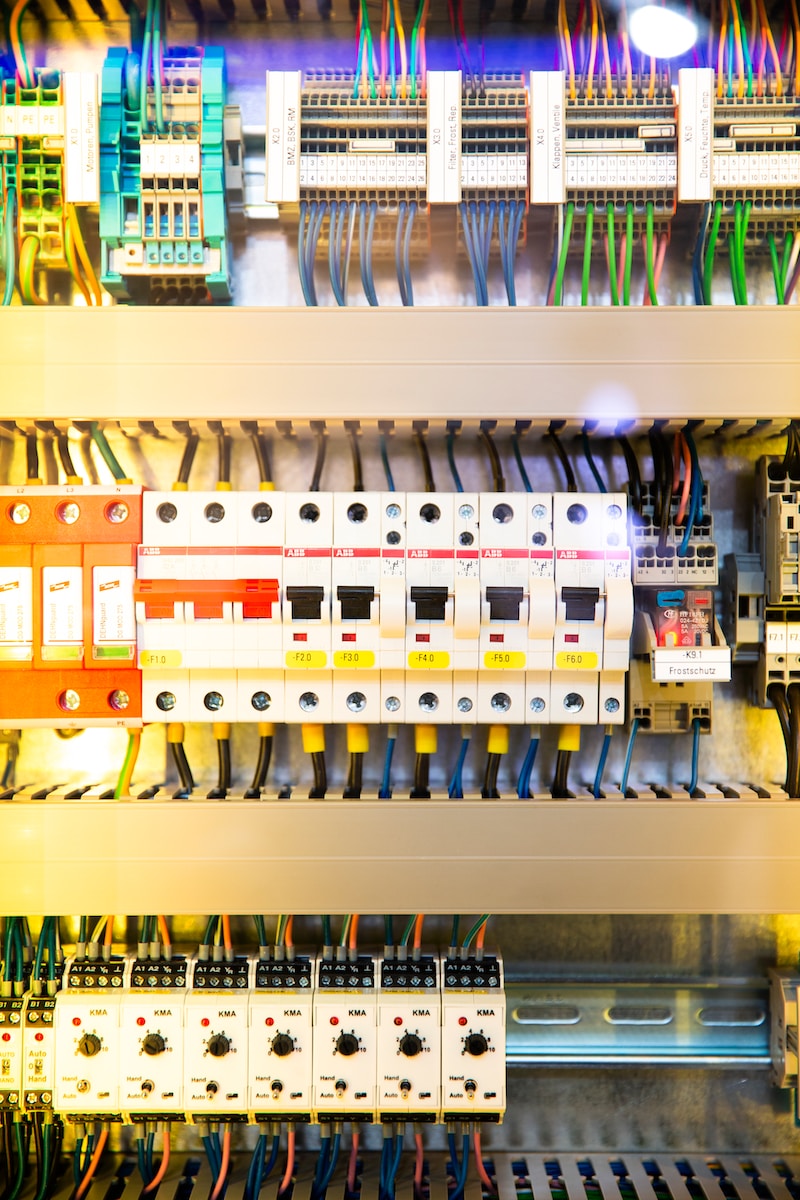

應用廣,投資報酬率高

免大量人力時間即可與系統或設備連結,全球已有多個應用案例,我們提供免費樣品測驗,服務客戶導入 SolVision。

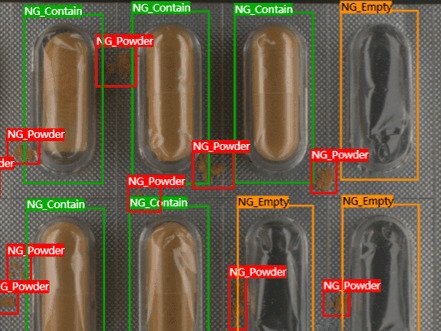

檢測速度快,訓練樣本少

藉軟體提升檢測速度,訓練樣本數僅需 1-5 張圖像,節省標註時間與成本。

簡易友善的介面與操作

易學免編程,直覺化界面允許同時標記多種缺陷類型,適合多種缺陷和特徵的分類任務。

非監督式分析比對

雜訊背景 OCR

AI 快速精準分類與計數