SolVisionCase Study

Beer Bottle Inspection Using AI

Case

Ensuring Quality in Reused Beer Bottles

To enhance environmental sustainability, many beer producers are adopting practices to recycle their beer bottles. After thorough cleaning and sterilization, these bottles undergo meticulous inspection to check for any damage or residue before they are reused.

Challenge

Detecting Stains and Mildew on Glass Bottles

Despite thorough disinfection, stains and mildew can sometimes persist on beer bottles. Identifying these defects early is crucial to remove flawed bottles before reuse. The inspection process is challenging due to the need to rotate and move the bottles and potential obstructions from product labels. These factors render manual inspection and conventional vision systems inefficient and impractical.

Solution

Enhanced Inspection with SolVision

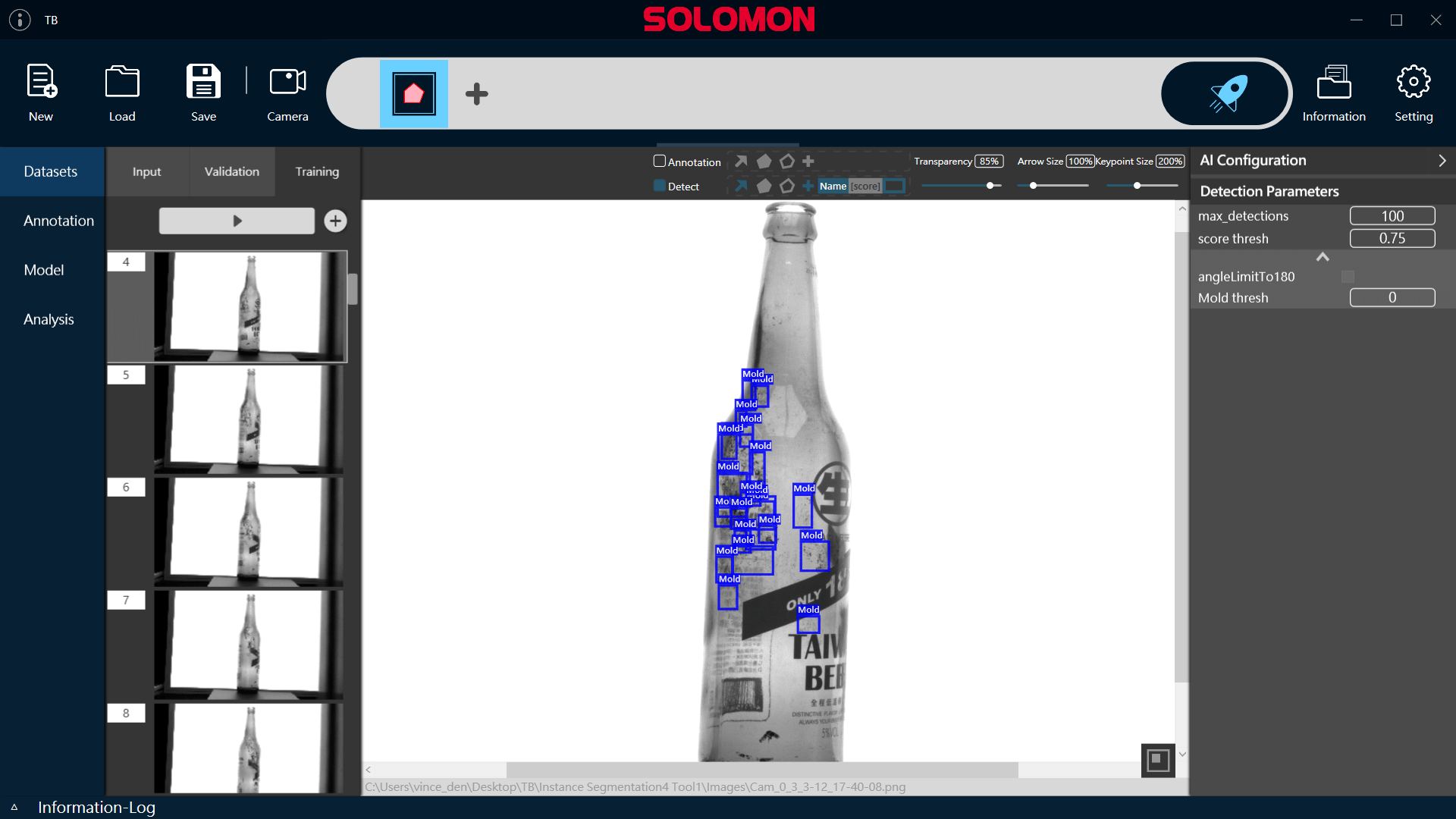

SolVision, an advanced AI vision system, elevates the inspection of beer bottles. Capable of training an AI model with a small set of sample images, SolVision learns to detect various types of stains and mildew. Its powerful segmentation tool accurately identifies the location, color, and features of defects in real-time on the production line. This thorough inspection ensures that all contaminated areas are promptly identified, making the cleaning and recycling process safer and more efficient.

Beer Bottle Inspection

Beer Bottle Defect Detection

Beer Bottle Inspection Results