SolVisionCase Study

Automating Quality Inspection of Lead Frames

AI defect detection for semiconductor lead frames

A key component of semiconductor assembly

In the semiconductor assembly process, lead frames connect chips to printed circuit boards, and are also used for chip carrying, circuit connection, and signal transmission. Almost all semiconductor packages require a lead frame, and they are produced by either photochemical etching or mechanical stamping. As semiconductor manufacturing becomes more sophisticated, the process of creating lead frames needs to improve in accuracy and yield.

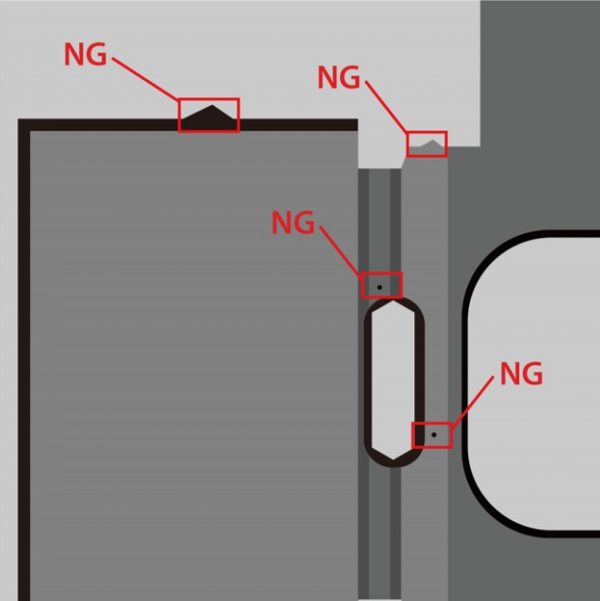

Complex backgrounds can affect detection rates

A single lead frame defect alone can result in complete failure of the semiconductor. Identifying defects early in the production process is therefore crucial to helping manufacturers avoid wasting time and resources. Common lead frame defects include edge burrs, impurities, stains, and scratches. When scanning surfaces, traditional vision systems tend to become confused when defects are too similar or blurred into the background, affecting inspection accuracy.

Recognizing detects with artificial intelligence

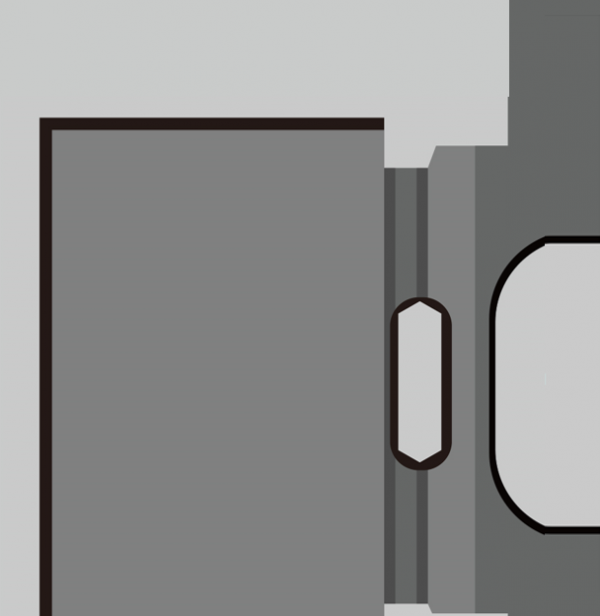

Powered by AI, SolVision is a visual inspection system capable of learning different production defects while minimizing detection errors. The software’s data augmentation tool helps to enlarge the AI model’s training scope so that even defects against complex or messy backgrounds can be recognized. Obscure flaws, black edges or spots, and edge protrusions can be also accurately identified.

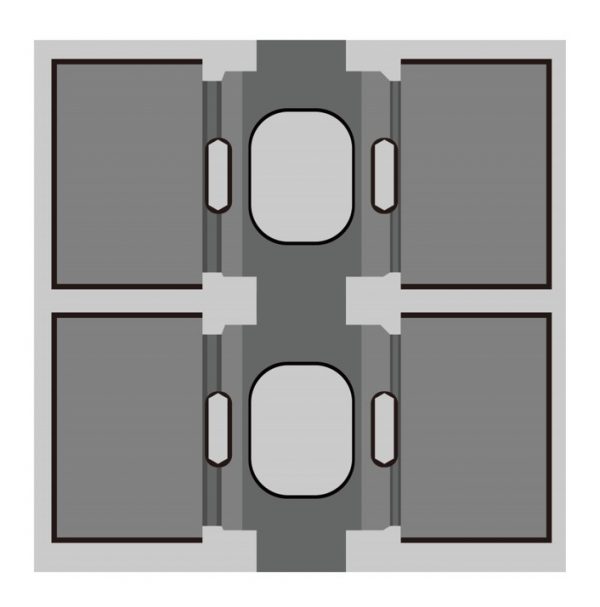

AI Inspection

Golden Sample

Black spots and raised edges