META-aiviCase Study

Loading and Unloading Tanker Trucks Safely Using AR + AI

Customer

The customer is a multinational manufacturer of polymer materials, synthetic rubber, and specialty chemicals with more than 50 years of experience.

Case

Chemical Tanker Truck Loading/Unloading

At chemical plants, tanker trucks load/unload potentially dangerous substances. To ensure the safety of personnel and assets during the loading/unloading process it is paramount to park the trucks correctly and minimize human error.

Challenge

Lack of an Effective and Precise SOP Verification Process

Tanker truck drivers and operators can get distracted and be prone to commit errors or cut corners when positioning the truck for loading/unloading. For this reason, the customer needed to implement a robust SOP verification system that also enabled the steps taken by operators to be tracked for compliance.

Solution

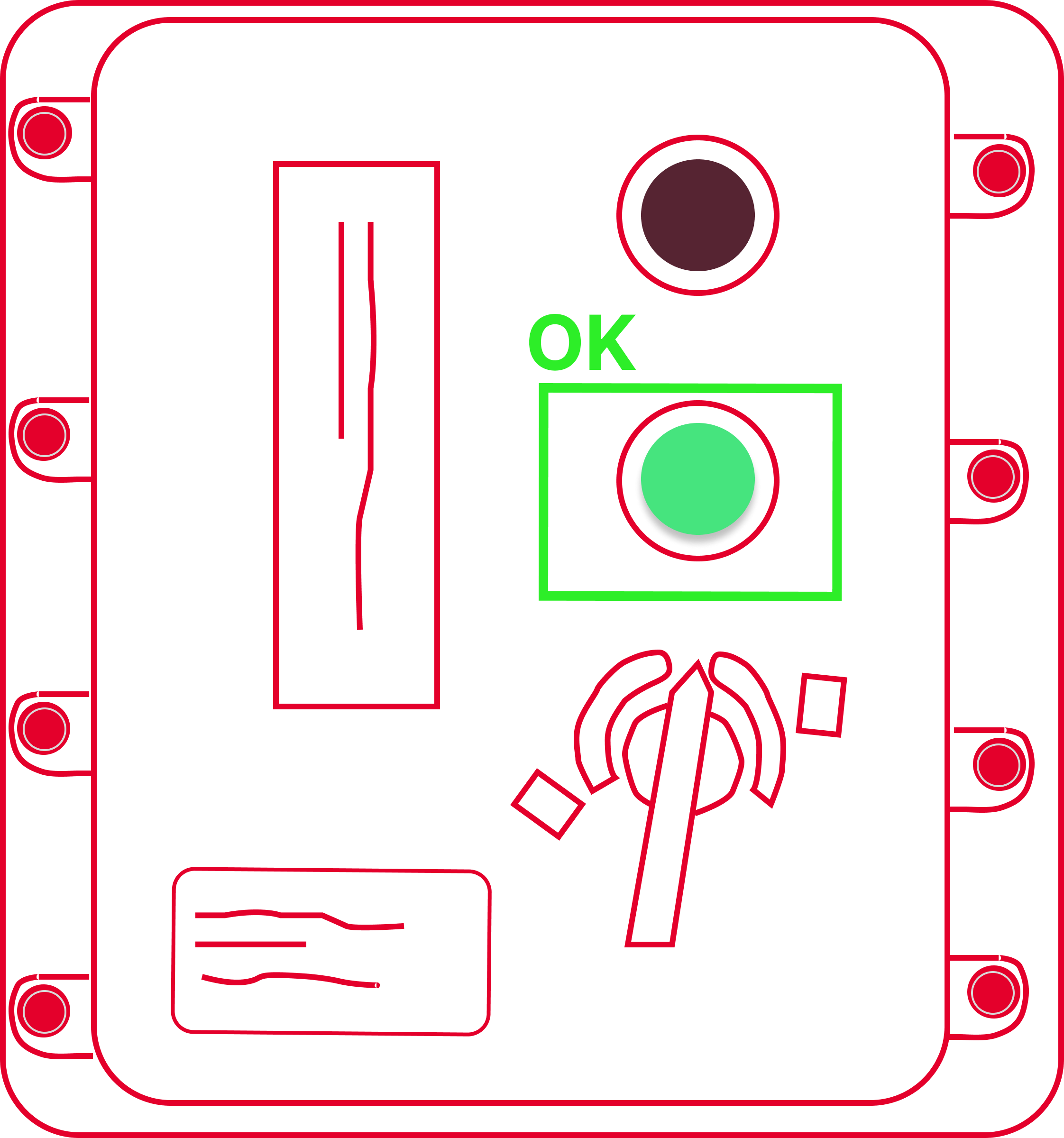

Using META-aivi and RealWear Glasses for SOP Validation

META-aivi uses AI detection to perform a step-by-step inspection of the chemical tanker loading/unloading process to ensure the operator is following the correct procedure. Solomon’s advanced AI helps operators verify that the truck’s wheels are properly secured by the wheel chocks, that the ground wire is connected, and that the static eliminator light is lit green to proceed safely. The inspection results are displayed on the AR device screen in real-time, guiding the operator to complete each of the necessary steps to safely load/unload the tanker truck (these results are also backed up to the customer’s server, creating a digital record for future reference).

META-aivi SOP Validation Process

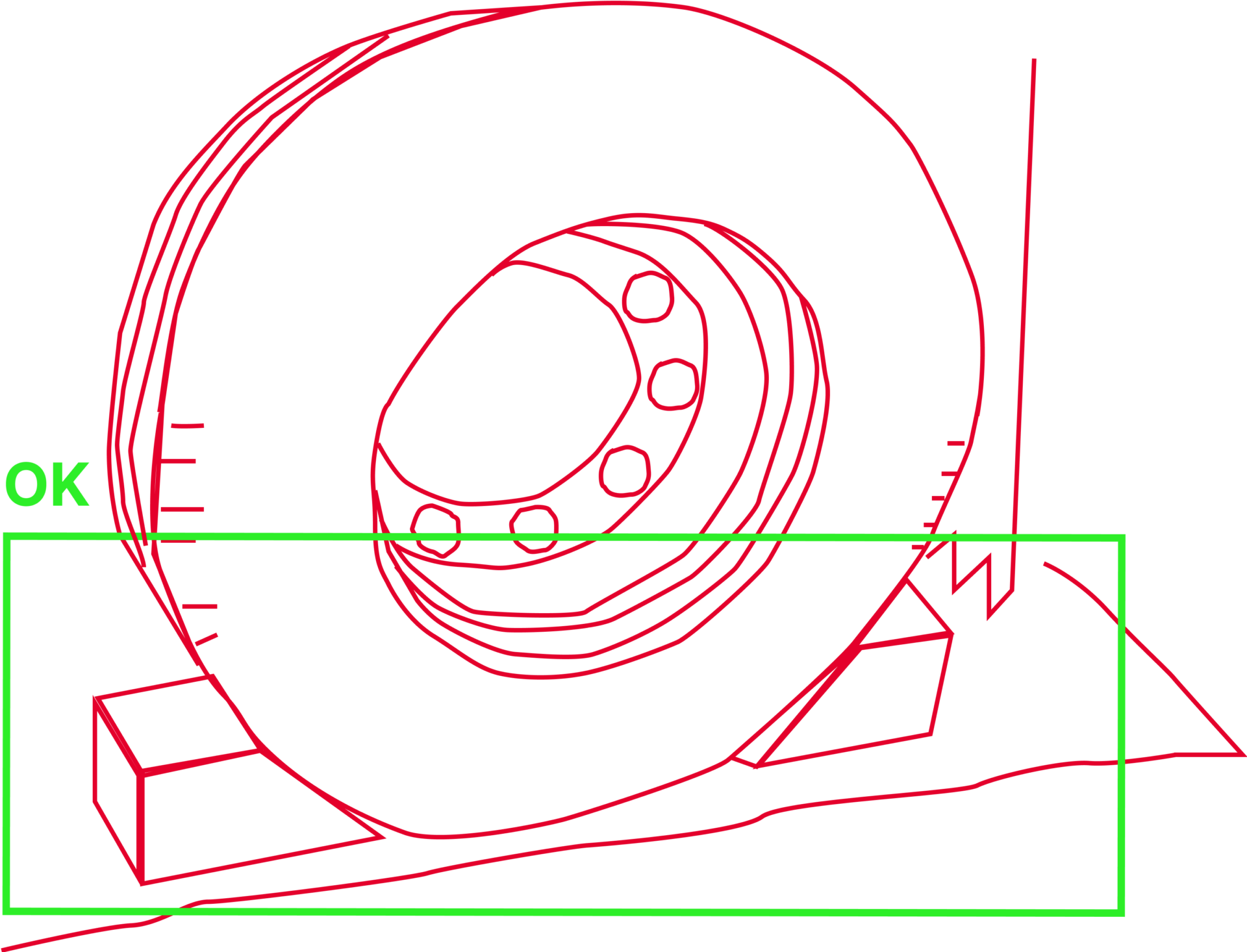

Step 1:

Confirm that the wheel chocks are positioned correctly

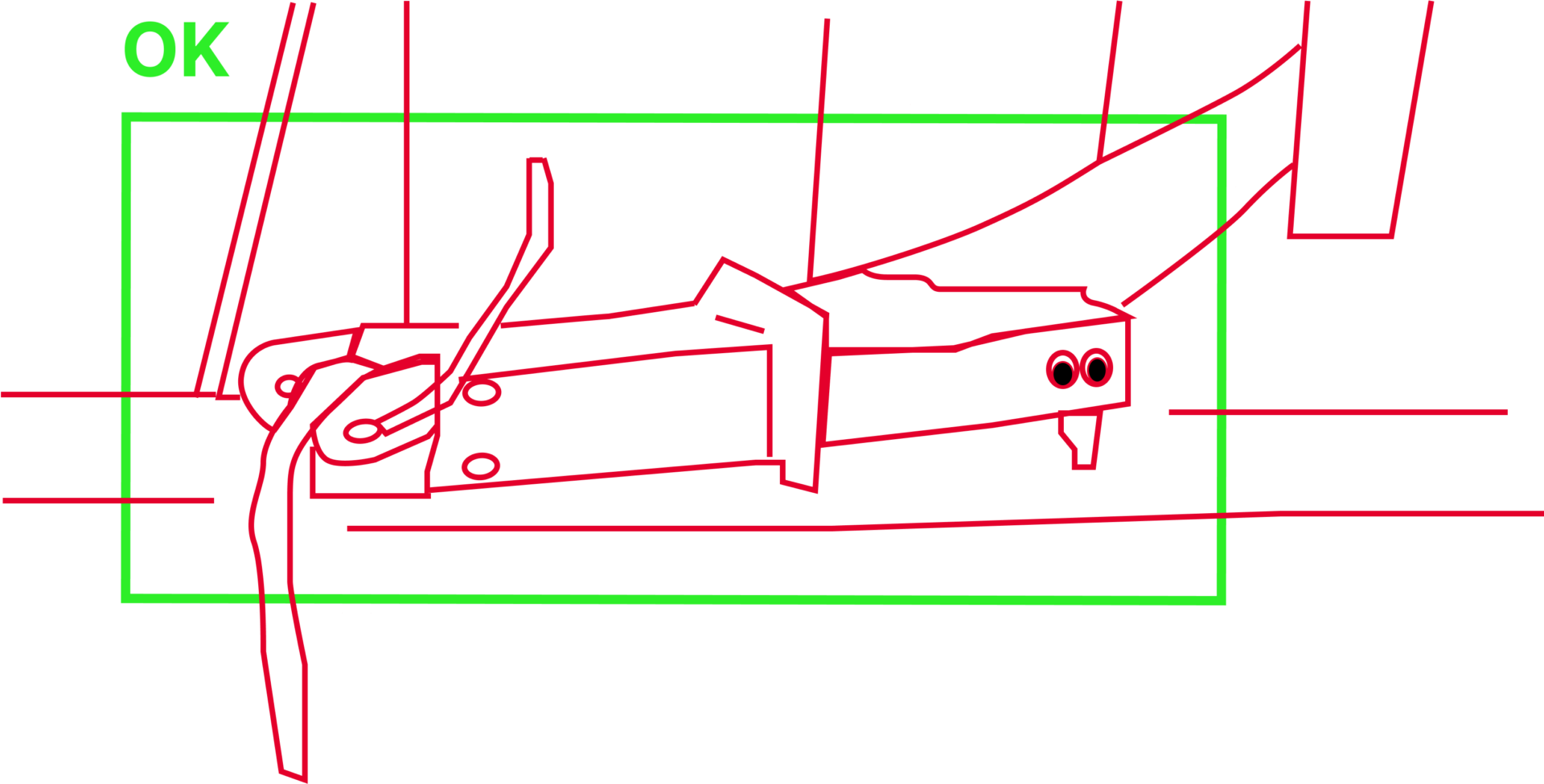

Step 2:

Ensure that the ground wire is properly connected