META-aiviCase Study

Electronic Components Soldering Inspection Using AI

Customer

The customer is a US-based optoelectronics company specializing in producing optical laser and detector components.

Case

Optimizing Electronic Components Inspection

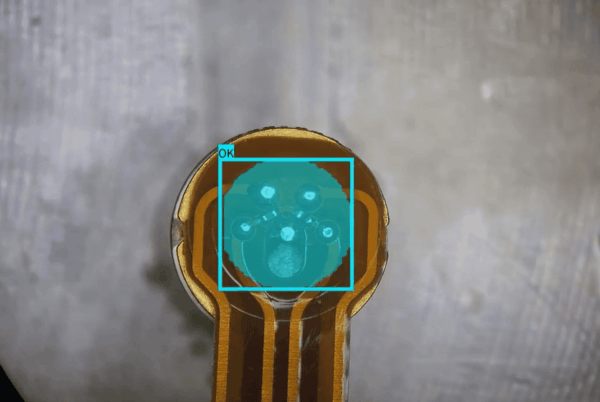

The customer sought to streamline their electrical component inspection process, particularly on their transceiver module production line. For soldering inspection, they rely on manual visual confirmation using a digital microscope after soldering, concentrating on five solder spots to ensure completion.

Challenge

Manual Inspection of Small-Scale Electrical Components

The main challenge stems from the manual inspection process, resulting in inconsistent inspection quality due to human error and fatigue. Despite using a microscope, the small size of the electrical components, some measuring only 3 mm, and even smaller solder spots, exacerbate visibility issues. This limitation complicates inspection and raises the risk of oversight.

Solution

Precise Inspection with META-aivi

META-aivi enhances inspection processes with AR + AI capabilities. By integrating META-aivi with digital microscopes, a comprehensive smart solution for detecting solder spot completion is achieved. META-aivi’s advanced AI vision technology accurately analyzes solder spots, even at the micro scale. This AI-integrated approach streamlines the inspection process, improving efficiency and accuracy while reducing dependence on manual inspection methods.