SolVisionCase Study

Product Packaging Inspection Using AI

Case

Product Packaging Defect Detection

Product packaging plays a critical role in shaping consumer perceptions and ensuring product integrity. For food manufacturers and other consumer goods producers, maintaining flawless packaging is essential for safeguarding quality and protecting brand reputation. However, printing defects such as missing information, misalignments, and smudged prints can lead to consumer confusion and harm brand trust.

Challenge

Limitations of Traditional Inspection Methods

Traditional inspection methods struggle to effectively identify printing defects on diverse product packaging, including soft aluminum, plastics, and other materials commonly used in consumer goods. The deformable nature and variability of packaging make it challenging to establish fixed rules for defect detection, rendering rule-based systems ineffective. As a result, manufacturers often rely on manual inspections, which are labor-intensive, inconsistent, and prone to errors. This approach slows down production, increases costs, and risks missing defects, highlighting the need for AI-driven solutions to ensure consistency and efficiency.

Solution

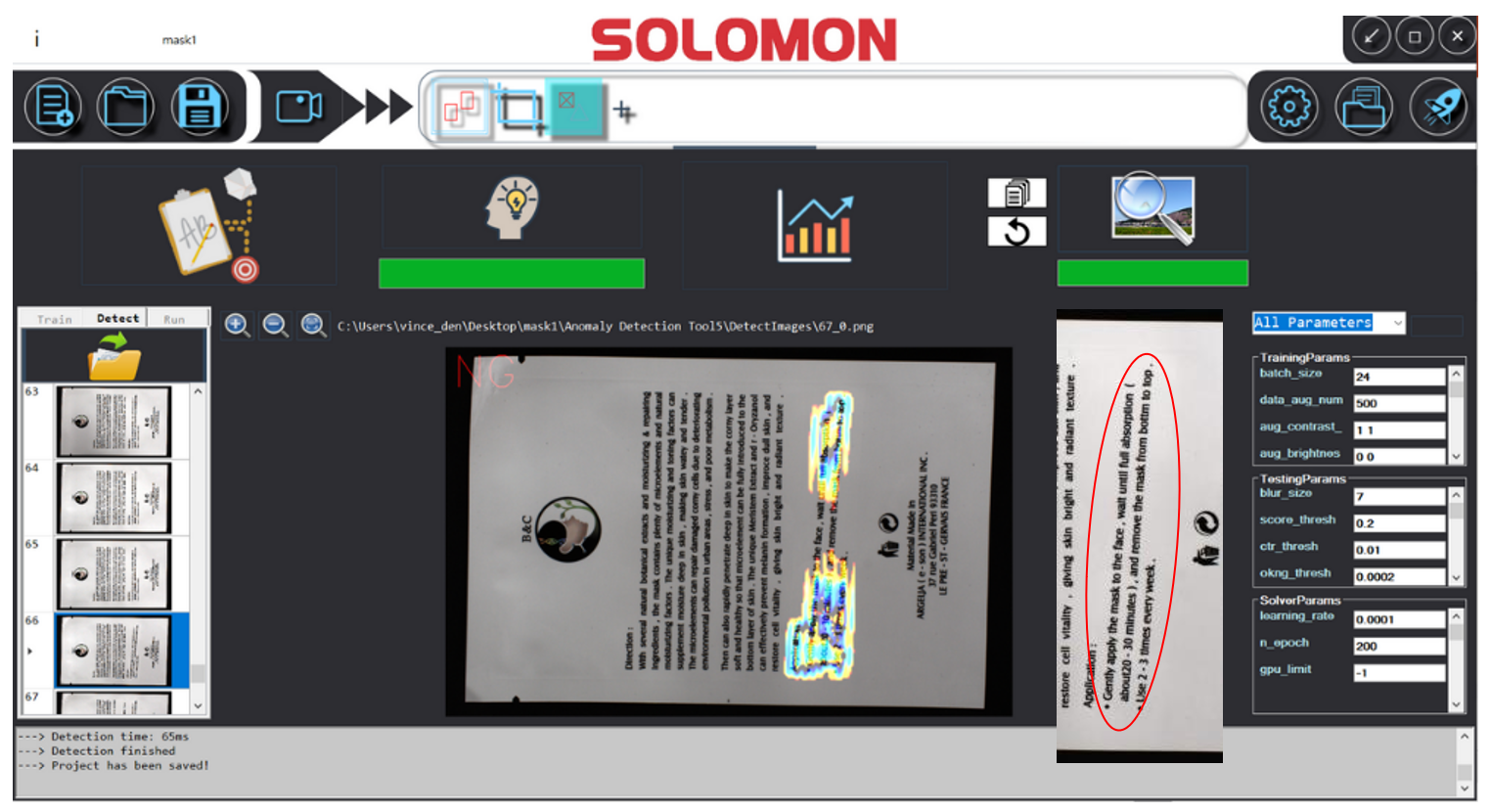

Automated AI-Powered Defect Detection

SolVision leverages advanced AI technology to automate the visual inspection of product packaging, overcoming the complexities of detecting printing defects. The system performs real-time image comparisons against a golden reference, identifying a wide range of anomalies such as text misprints, character distortions, image misalignments, and color deviations. Each defect is precisely marked, allowing for efficient sorting and processing of non-conforming items. This approach ensures consistent quality control, reduces human error, and optimizes production efficiency.