SolMotionCase Study

Vision Guided Robotics in Automotive Processes

Feature Detection for Car Body Sealing

Case

Advanced Automation for High-Quality Automobile Production

The production of automobiles depends on complex multi-stage processes that must be meticulously synchronized to ensure the delivery of high-quality products. A crucial aspect of these processes is the precise positioning of various parts, which often necessitates advanced robot support and precision beyond what traditional vision systems can provide.

Challenge

The Limitations of Conventional Laser Triangulation Solutions

To ensure efficient automotive sealing processes and prevent material waste and robot collisions, precise execution is paramount. However, using conventional laser triangulation solutions for scanning large automotive parts presents challenges. These solutions have a limited field of view, which can result in significant deviations or incorrect part locating, ultimately leading to substandard production.

Solution

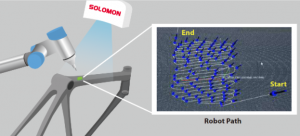

SolMotion AI and 3D Feature Detection Capabilities

Solomon’s VGR solution, SolMotion, utilizes cutting-edge AI and 3D technologies to optimize complex manufacturing, especially in car sealing. SolMotion can simultaneously learn multiple car models and quickly identify them on the production line using 3D point cloud data. The system’s machine learning-based recognition empowers multi-robot setups to adapt sealing paths in real-time, ensuring precise car location despite any part shifts or orientation changes. This leads to enhanced manufacturing productivity and accuracy.